AGV 및 AMR 드라이브는 일반적으로 서보 모터, 감속 장치, 브레이크, 타이어로 구성되며 엔코더로 로봇의 이동, 조향, 정지를 제어합니다. 엔코더는 속도 모니터링에 있어 특히 위험 지점을 보호하기 위한 안전 레이저 스캐너와 함께 안전 기능을 갖춘 이동식 로봇의 필수 구성 요소입니다.

AGV의 각 차축/바퀴는 두 모터 간의 토크 차이만큼 그 축을 중심으로 이동합니다. 각 차축 드라이브의 각 위치 피드백으로 폐루프 제어가 가능합니다.

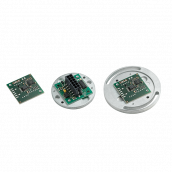

RLS는 AGV 및 AMR 산업에 필요한 마그네틱 엔코더 분야를 선도하는 전문 제조 및 공급업체입니다. 다양한 설계 변형과 산업 표준 출력 옵션을 갖춘 RLS 엔코더는 설치가 용이할 뿐만 아니라 수명 또한 깁니다.

AGV - 무인 운반 차량은 휴대형 로봇으로 바닥에 표시된 긴 선이나 와이어를 따라 이동하거나 무선 전파, 비전 카메라, 마그넷, 레이저 등을 사용해 움직입니다.

AMR - Autonomous Mobile Robot은 온보드 센서와 프로세서를 사용하여 물리적인 안내 또는 표식 없이 자재를 자율적으로 움직이는 로봇(차량)입니다.

AGV와 AMR은 자동차 산업, 물류, 스마트 물류 창고, 식음료, 제약, 인쇄 산업 등 다양한 분야에서 무거운 물건을 반복적으로 운반하는 데 사용됩니다. 좁은 복도에서도 작업이 가능하며 높은 선반에 물건을 올리거나 내릴 수 있어 물류 창고의 수용 능력을 향상시킬 수 있도록 설계되었습니다. AGV/AMR은 모든 산업 분야에서 특히 물류 병목이 증가하고 있는 요즈음 큰 부가 가치를 제공하며 유연한 물류 처리를 가능하게 해줍니다.

AGV/AMR이 바퀴의 정확한 위치를 판별하기 위해서는 엔코더가 정확한 위치 정보를 제공해야 합니다. 속도와 방향을 조절하려면 엔코더를 통해 정밀하고 안전한 작업을 보장할 수 있어야 합니다.

엔코더는 크기가 작아야 합니다. 많은 AGV / AMR은 스마트 물류 창고의 요건을 충족할 수 있도록 작은 크기로 설계되었습니다. 드라이브 시스템 내 간편한 설치도 장점입니다.

공장이나 물류 창고에서 AGV 또는 AMR을 사용하는 경우 바닥이 고르지 않고 물건들이 어질러져 있어 불가피하게 어느 정도의 충격을 유발하게 됩니다. 따라서 충격과 진동에 강하면서 복잡한 환경에서도 정확성을 유지할 수 있는 엔코더가 필요합니다.

AGV 및 AMR 드라이브는 일반적으로 서보 모터, 감속 장치, 브레이크, 타이어로 구성되며 엔코더로 로봇의 이동, 조향, 정지를 제어합니다. 엔코더는 속도 모니터링에 있어 특히 위험 지점을 보호하기 위한 안전 레이저 스캐너와 함께 안전 기능을 갖춘 이동식 로봇의 필수 구성 요소입니다.

AGV의 각 차축/바퀴는 두 모터 간의 토크 차이만큼 그 축을 중심으로 이동합니다. 각 차축 드라이브의 각 위치 피드백으로 폐루프 제어가 가능합니다.

Autonomous mobile robots (AMR) are transforming industry by automating internal transportation and material handling tasks, bringing a new level of efficiency, flexibility and cost effectiveness to modern operations. Companies are under increasing pressure to optimize workflows and reduce downtime. AMRs offer a dynamic solution by autonomously navigating complex environments, adapting to changes in real time and performing tasks without human intervention.