AGV和AMR驱动单元通常由伺服电机、减速器、制动装置和轮胎组成,需要由编码器来控制车辆的运动、转向和停止。在速度监控方面,尤其是与激光扫描仪配合工作以保证安全性,避免进入危险区域时,编码器是带有安全功能的车辆中的一个关键部件。

通过两个电机之间的扭矩差,AGV的每个车轴/车轮可以沿轴向实现转向。每个车轴驱动器提供的角度位置反馈可以实现闭环控制。

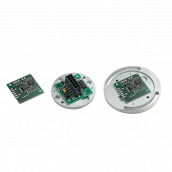

对于自动导引运输车 (AGV) 和自主移动机器人 (AMR) 行业,RLS是领先的磁编码器制造商和供应商。RLS编码器可提供各种设计型号和行业标准输出选项,多年来一直以安装便捷和运行可靠著称。

自动导引运输车是一种便携式机器人,可按地面上标记的长线或铺设的电线行驶,或使用无线电波、视觉摄像头、磁体或激光进行导航。

AMR — 自主移动机器人是一种机器人(车辆),其使用车载传感器和处理器自主移动物料,无需物理导引或标记。

AGV和AMR用于在各种应用环境中重复移动大量物料,包括汽车制造、物流、智能仓储、食品饮料、制药和印刷等行业。它们可在狭窄的通道内工作,并将物料放置在极高的货架上,因此能够提升仓储容量利用率。无论您的企业属于哪个行业领域,AGV/AMR都可使物流运输方式更为灵活,从而为企业显著提高附加值 — 尤其是在物流瓶颈日益增长的当下。

为了使AGV/AMR能够确定车轮的确切位置,必须有编码器提供精确位置。为了控制速度和方向,编码器对于确保精确、安全操作至关重要。

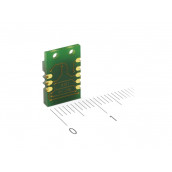

编码器的结构必须紧凑。许多AGV/AMR的结构设计都非常紧凑,以满足智能仓储的需求。驱动系统的便利安装也是一大优势。

当在工厂或仓库中工作时,由于地面不平或碰到杂乱摆放的物品,AGV或AMR不可避免地会产生某些冲击和振动。因此选择的编码器必须具有极高的抵抗冲击和振动的能力,以维持其在复杂环境下的精度。

AGV和AMR驱动单元通常由伺服电机、减速器、制动装置和轮胎组成,需要由编码器来控制车辆的运动、转向和停止。在速度监控方面,尤其是与激光扫描仪配合工作以保证安全性,避免进入危险区域时,编码器是带有安全功能的车辆中的一个关键部件。

通过两个电机之间的扭矩差,AGV的每个车轴/车轮可以沿轴向实现转向。每个车轴驱动器提供的角度位置反馈可以实现闭环控制。

Autonomous mobile robots (AMR) are transforming industry by automating internal transportation and material handling tasks, bringing a new level of efficiency, flexibility and cost effectiveness to modern operations. Companies are under increasing pressure to optimize workflows and reduce downtime. AMRs offer a dynamic solution by autonomously navigating complex environments, adapting to changes in real time and performing tasks without human intervention.