AGV 和 AMR 通常由伺服馬達、減速器、制動器和輪胎組成,且需要編碼器來控制載具的移動、轉向和停止。在監控速度時,尤其在結合安全雷射掃描器以預防危險位置時,編碼器就是讓載具具備安全功能不可或缺的元件。

AGV 的每個車軸/車輪因兩個馬達的扭矩差而繞著軸線轉向。每個車軸的驅動產生的角度位置回饋則實現了閉合迴路控制。

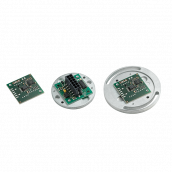

RLS 是 AGV 和 AMR 產業專用磁性編碼器的領導製造商與供應商。多年來,RLS 編碼器具備多種的設計版本和業界標準輸出選項,並提供簡易的安裝及可靠的操作。

AGV - 自動導引車是可攜式的機器人,依照地板上標記的長線或配線移動,或使用無線電波、視覺攝影機、磁鐵或雷射進行導航。

AMR - 自主移動機器人是一種機器人(載具),採用機載感測器和處理器,在無需實體引導或標識的情況下自動移動材質。

在汽車產業、物流、智慧倉儲、食品與飲料、製藥以及印刷業的多種應用中,AGV 和 AMR 可應用於反覆搬移大量原物料。這些 AGV 的設計目的是在狹窄通道工作、觸及高處貨架,並提升倉儲容量。AGV/AMR 可為所有部門的公司帶來可觀的附加價值並帶動靈活的物流,尤其在物流瓶頸增加的時期更顯有效。

為了使 AGV/AMR 能在判別齒輪的確切位置,編碼器必須提供精準的位置。為了控制速度和方向,編碼器必須能保證精確和安全運作。

編碼器的外型必須小巧。許多 AGV/AMR 的設計都很小巧,這是為了符合智慧倉儲的需求。驅動系統的安裝簡易也是另一項優勢。

AGV 或 AMR 在廠房或倉庫中運作時,由於地面不平整與物件雜亂,無可避免地會造成一定程度的震盪和衝擊。因此,選用的編碼器必須可高度抗衝擊與振動,才能在複雜環境中維持精準。

AGV 和 AMR 通常由伺服馬達、減速器、制動器和輪胎組成,且需要編碼器來控制載具的移動、轉向和停止。在監控速度時,尤其在結合安全雷射掃描器以預防危險位置時,編碼器就是讓載具具備安全功能不可或缺的元件。

AGV 的每個車軸/車輪因兩個馬達的扭矩差而繞著軸線轉向。每個車軸的驅動產生的角度位置回饋則實現了閉合迴路控制。

Autonomous mobile robots (AMR) are transforming industry by automating internal transportation and material handling tasks, bringing a new level of efficiency, flexibility and cost effectiveness to modern operations. Companies are under increasing pressure to optimize workflows and reduce downtime. AMRs offer a dynamic solution by autonomously navigating complex environments, adapting to changes in real time and performing tasks without human intervention.