LinACE™ with digital outputs vs. LVDT sensor

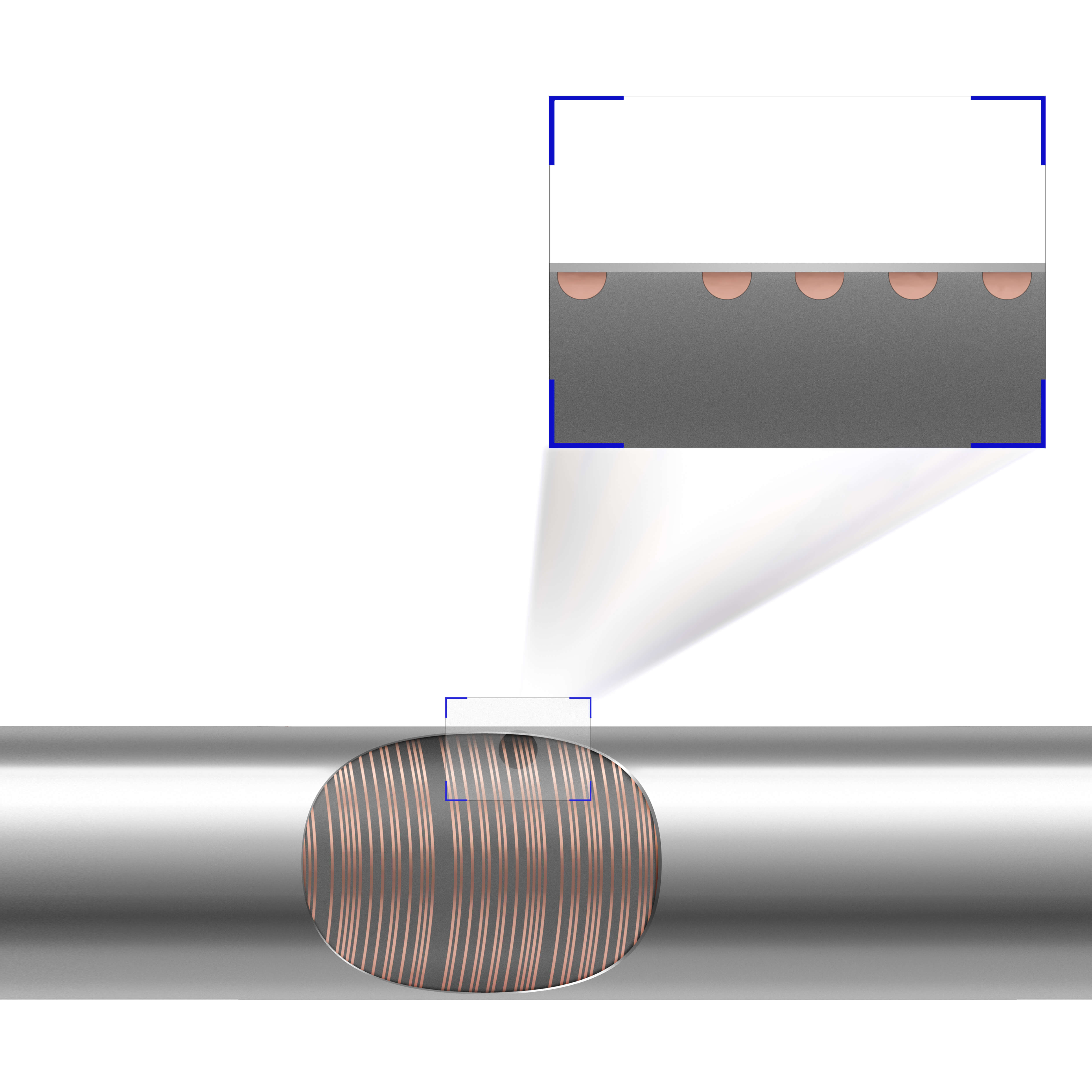

LinACE™是一种机电传感器,用于将物体的直线运动转换为电信号。

与模拟输出相比,数字输出具有多种优势,因为它们不易受到电磁干扰的影响,且允许内置自监控,甚至可以采用CRC等错误检测代码。所有这些优势都使得可靠性更高,尤其是在使用更长的电缆时。

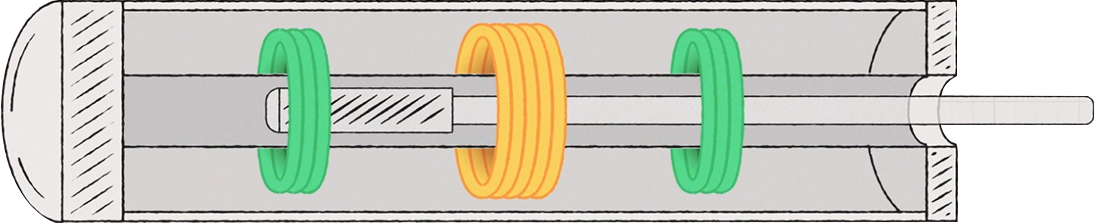

LVDT通常由围绕一根管排列的三个线圈组成。中间的线圈为初级线圈,两个外侧的线圈为次级线圈。一个铁磁芯沿轴滑动。

当磁芯移动时,初级线圈和两个次级线圈之间的磁连接发生变化,导致感应电压发生变化。次级线圈中的感应电压差被转换为位置信息。

为什么选择LinACE,而不是LVDT?

- 重量轻(无需沉重的线圈)

- 紧凑型设计

- 数字输出、优异的诊断功能和可靠性

- 温度稳定性

- 低输出纹波 — 信号噪声

- 测量长度为20 mm或更长时,仍可确保精度

- 无预行程或后行程

有关LinACE的详细信息,请访问LinACE网站。

紧凑型设计

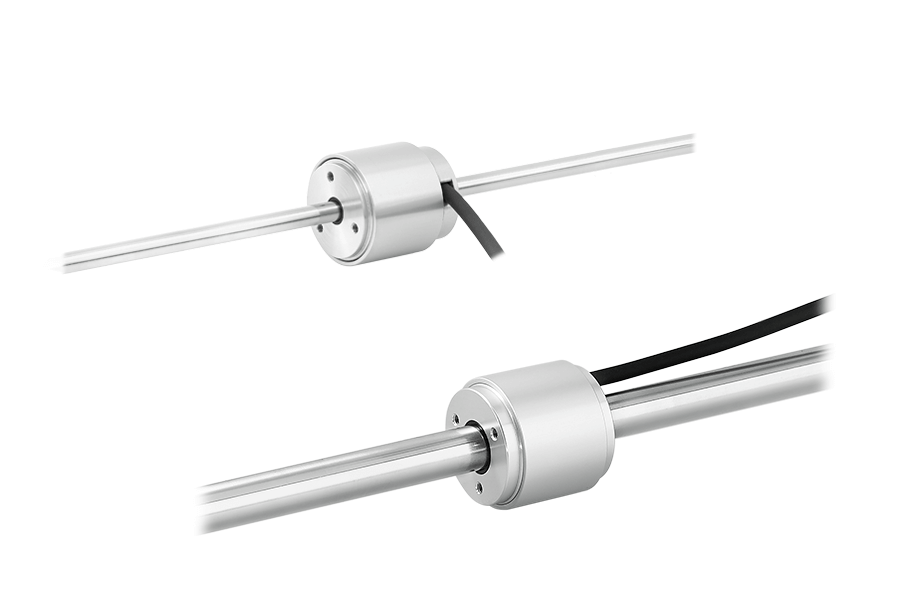

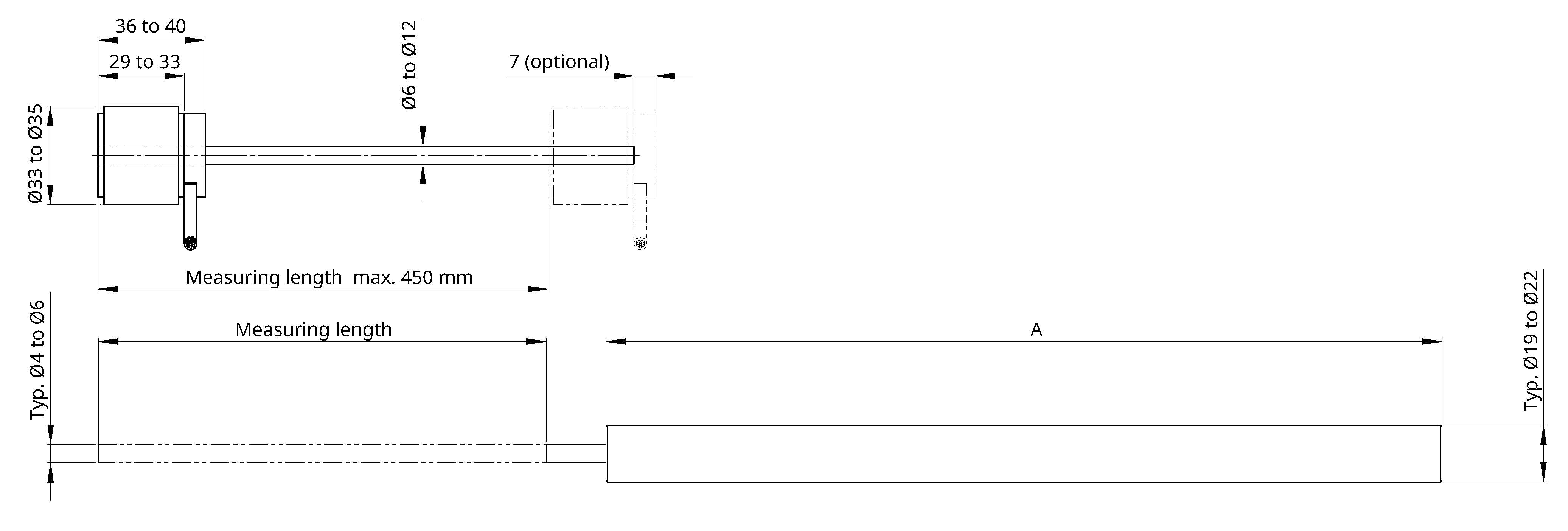

与LVDT不同,LinACE读数头的长度不取决于测量长度。LinACE的读数头长度为29 mm至40 mm(最大),直径最大为35 mm。

LVDT传感器要求线圈长度大于测量长度。因此,传感器头的长度与测量长度并行增加。

测量长度为20 mm或更长时,LVDT的典型直径为19 mm或22 mm。处理电子元件可以集成到LVDT中,也可以单独外置。如果采用集成方式,传感器头的长度会更长。如果采用外置方式,则需要:

- 附加接线、

- 安装空间及

- 额外成本。

LinACE与LVDT:读数头长度与质量

| 测量长度 [mm] | 长度 (mm) | 质量 (g) | ||

| LinACE | LVDT (A) | LinACE | LVDT | |

| 20 | 29 | 140 | 94 | 130 |

| 100 | 29 | 230 | 111 | 265 |

| 150 | 29 | 280 | 122 | 325 |

| 300 | 29 | 450 | 144 | 520 |

- 对于LVDT:估计典型值(带有集成式处理电子元件)。

- 对于LinACE:带轴向出线电缆,1 m电缆和6 mm编码轴直径。

数字输出、优异的诊断功能和可靠性

LinACE编码器具有异步串行、PWM、SSI和BiSS等输出类型,可选择的分辨率范围在10 µm至0.5 µm之间,速度最高可达5 m/s。

LinACE编码器具有内置的高级自监控功能,可持续检查各种内部参数。错误报告、报警以及其他状态信号可从所有数字接口获得。无需信号调节器或其他电子设备。

LVDT传感器通常只有模拟或LVDT输出,而没有状态信息。对于LVDT输出,需要单独的处理电子元件(或信号调节器)。

LVDT信号调节器示例,DEWESoft生产的DSI-LVDT适配器:

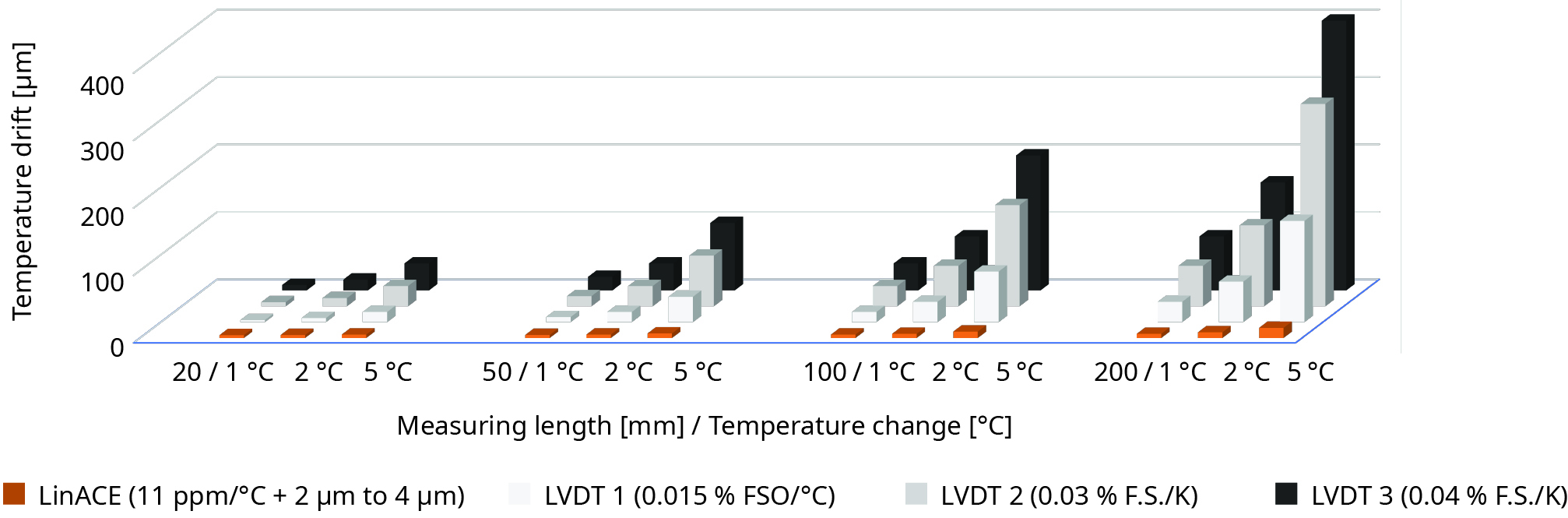

温度稳定性

随着温度波动,我们可以预见会出现一些位置漂移。LVDT传感器的温度系数通常为0.015%/K至0.04%/K,这会导致相当大的温度漂移,尤其是当测量长度较长时。

LinACE位置测量值随温度的变化则仅由编码碳合金钢轴和读数头铝制外壳的热膨胀引起,这通常在设备框架的热膨胀范围内。

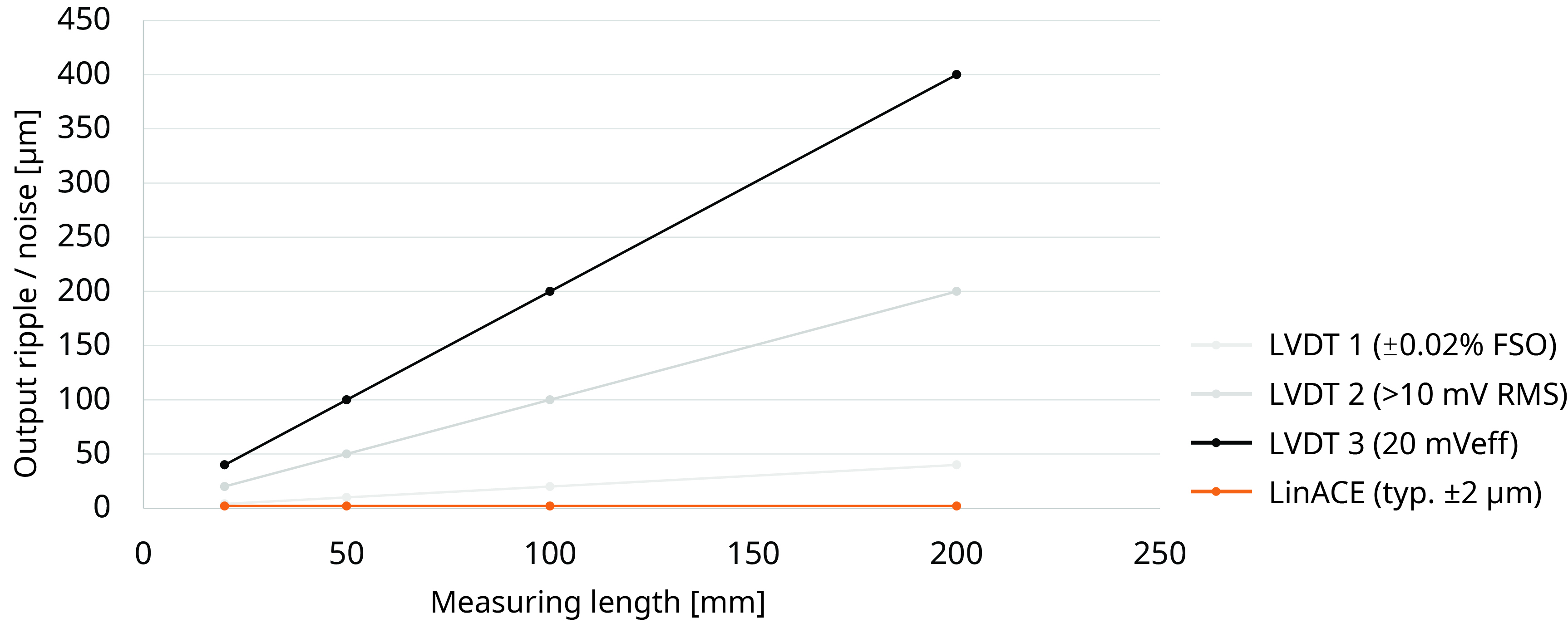

输出纹波 — 信号噪声

LVDT通常存在输出纹波或信号噪声,以mV (RMS) 或mV (eff) 为单位。测量长度越长,它们对精度的影响越大。输出纹波或噪声通常在测量长度的中间较低,在两端较高。对于150 mm的测量长度,噪声水平可能在30 µm至300 µm之间。对于高端LVDT,噪声水平在测量范围的中间可低至3 µm。

LinACE传感器的信号噪声与测量长度无关。正常噪声值小于2 µm。

信号噪声与传感器测量长度

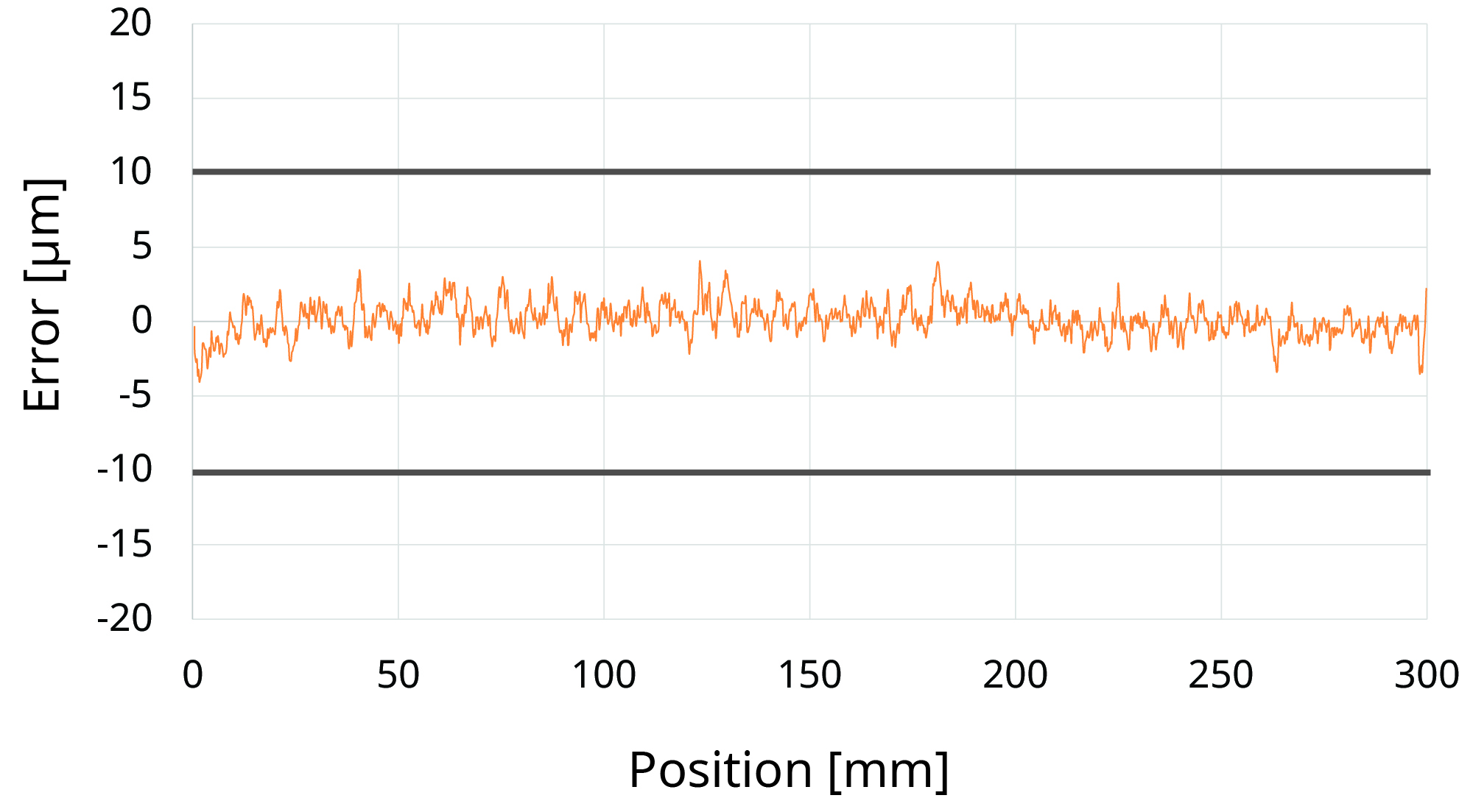

测量长度为20 mm或更长时,仍可确保精度

LinACE编码器的分辨率为10 µm至0.5 µm,精度为±100 µm至±5 µm。测量长度不超过100 mm时,精度可达±5 µm。测量长度不超过450 mm时,精度可达±10 µm。下方的LinACE精度图显示了测量长度为300 mm且精度为±10 µm时的典型精度。

但是,我们必须考虑由于编码轴和铝制外壳的热膨胀而导致的温度漂移。

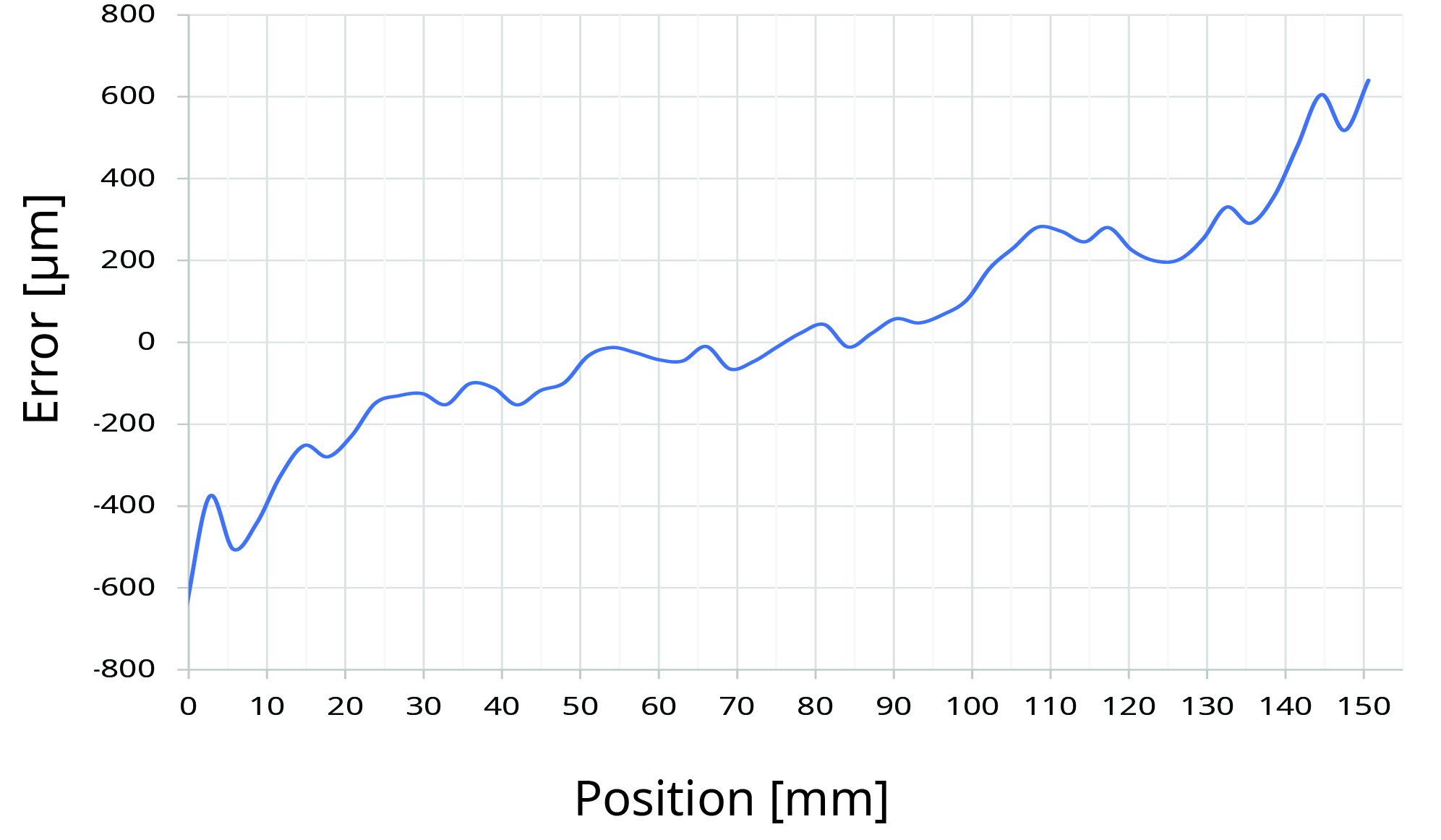

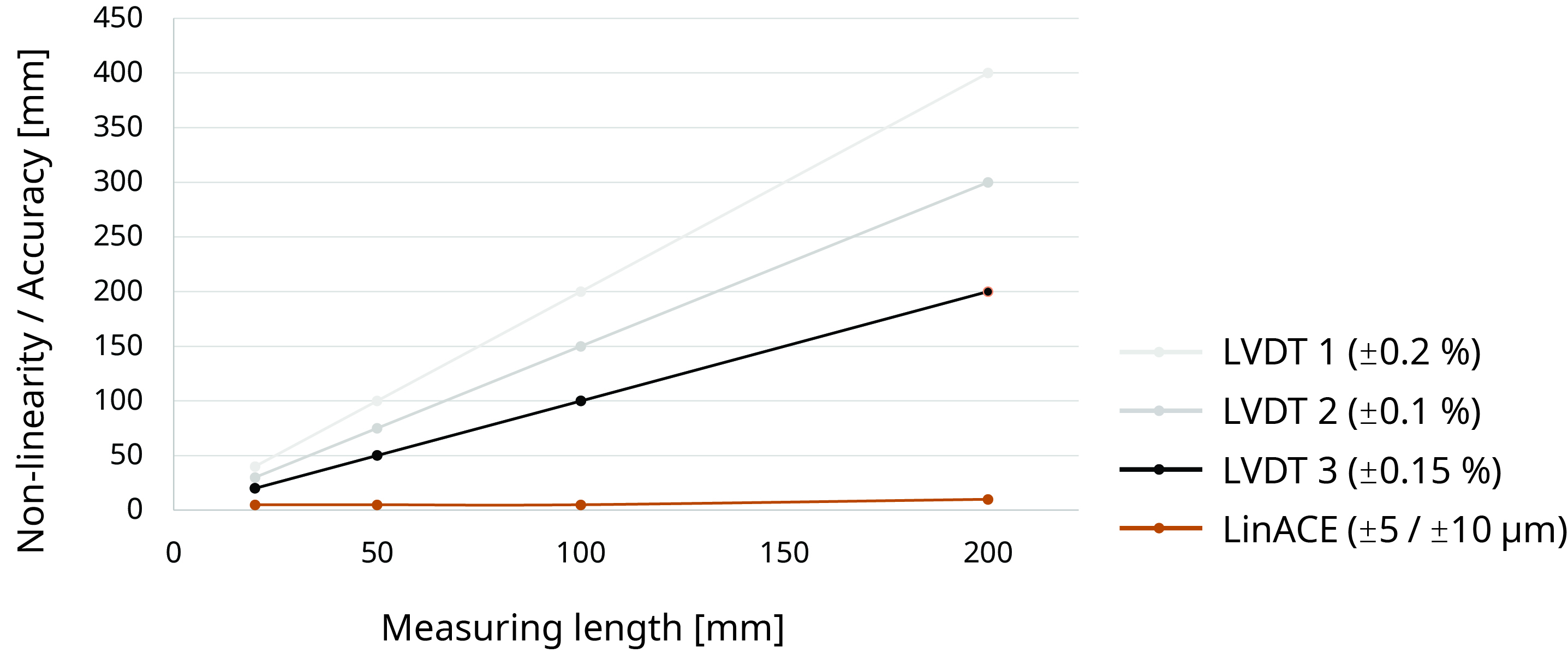

LVDT传感器具有0.1%至0.5%的典型非线性度。因此,测量范围不超过10 mm时,LVDT的精度和分辨率非常出色(±5 mm行程时为±5 µm,非线性度为0.1%)。但是,当行程达到100 mm时,预计非线性度将变为100 µm或更大。为获得更好的线性度,可在客户端执行额外的校准。

下方的LinACE与LVDT精度图显示了非线性度为0.1%、0.15%和0.2%时LVDT的精度。正如所见,LinACE在较长的测量长度下具有明显的精度优势。

LinACE与LVDT精度图

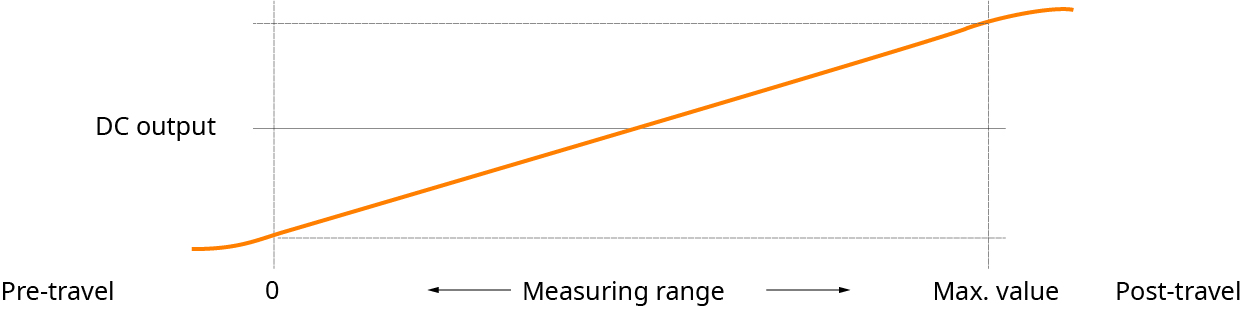

无预行程或后行程

LinACE编码器没有预行程或后行程。编码轴从开始到结束的整个行程都可以不受限制地使用。

在指定的核心运动范围内,LVDT传感器具有线性度非常高的输出,但在输出线性度降低的扩展范围内,也可以使用LVDT传感器。该范围通常在几毫米以内。

- 预行程:从LVDT传感器完全向外的位置(移动元件靠在机械挡块上)到LVDT测量范围起点的机械运动。

- 后行程:从LVDT测量范围终点(向内)到LVDT传感器完全向内的位置(移动元件靠在机械挡块上)的机械运动。

规格比较

| LinACE | LVDT | |

| 测量长度 | 从20 mm至450 mm | 从0.254 mm至700 mm |

| 编码器长度 | 测量长度 + 29 mm至40 mm | 约为测量长度 x 2 |

| 分辨率 | 达0.5 µm(20 mm范围时 >15位) | <15位 |

| 精度 | 达±5 µm | |

| 非线性 | 100 mm范围时< 0.01% | 0.1 / 0.2 / 0.25 / 0.5(总标度的百分比) |

| 重复精度 | 1 µm | 0.01%至0.1%(100 mm范围时10 µm至100 µm) |

| 输出带宽 | 2000 Hz | 15 Hz至500 Hz |

| 输出 | 异步串行、PWM、SSI、BiSS | 模拟、RS485 |

| 电源电压 | 5 V | 5 V至12 V或10 V至30 V |

| 功耗 |

典型值500 mW* 最大值600 mW* |

300 mW至700 mW |

| IP防护等级 | IP40 | IP40至IP68 |

| 温度 | -30 °C至+105 °C |

0 °C至+65 °C或 -40 °C至+200 °C |

* 无输出负载。