背景

Metal additive manufacturing, commonly referred to as 3D metal printing, has changed the way the industry approaches production. By building metal components layer by layer instead of traditional subtractive processes, this technology has enabled unprecedented design flexibility, reduced material waste, and opened up new ways for rapid prototyping and on-demand production.

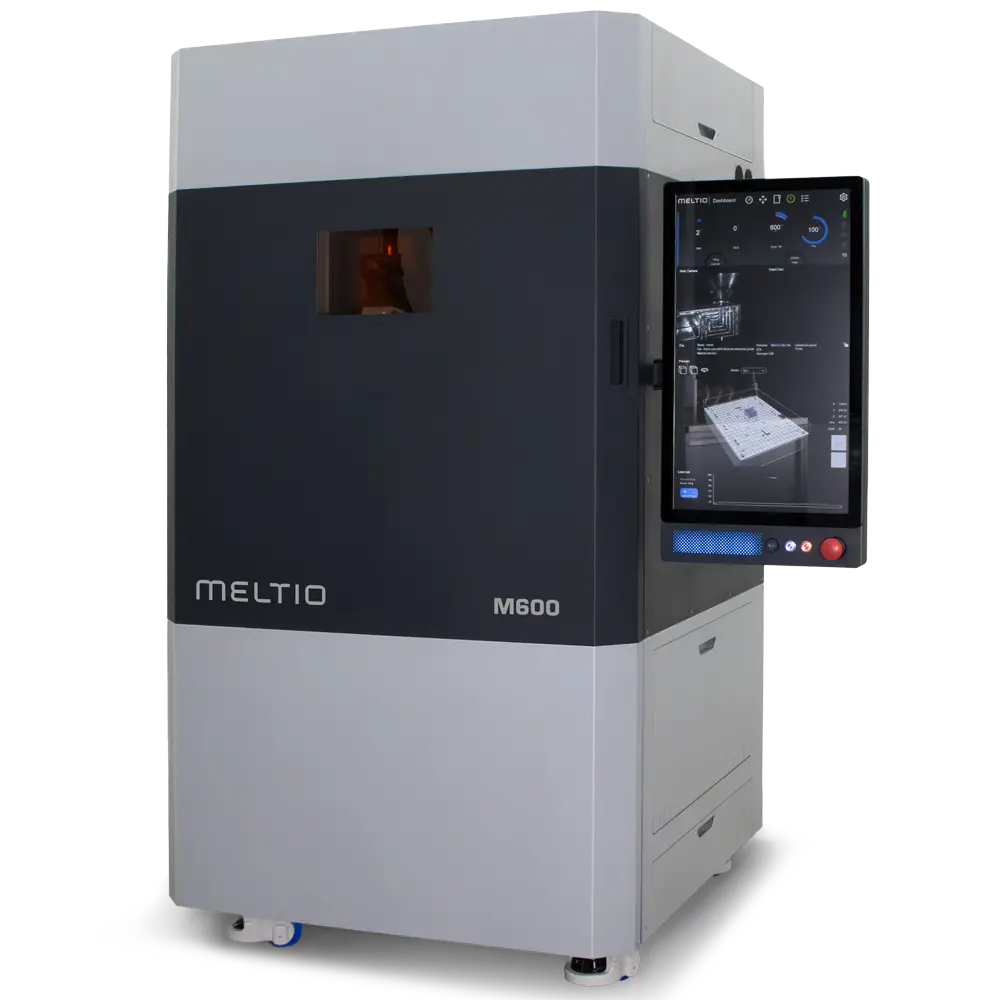

Meltio, a Spanish manufacturing company, develops high-performance, affordable, and easy-to-use metal 3D printing solutions. Their technology is designed for applications such as industrial prototyping, mold and die, maintenance, and repair. They can be seamlessly integrated into industrial environments or university laboratories.

Meltio's open material platform supports a wide range of production series, from one-offs and small batches to mass production, and eliminates the need for complex industrial infrastructure.

By providing accessible metal 3D printing solutions, Meltio increases production efficiency, reduces costs, and enables new design possibilities that drive the future of flexible and effective manufacturing.

課題

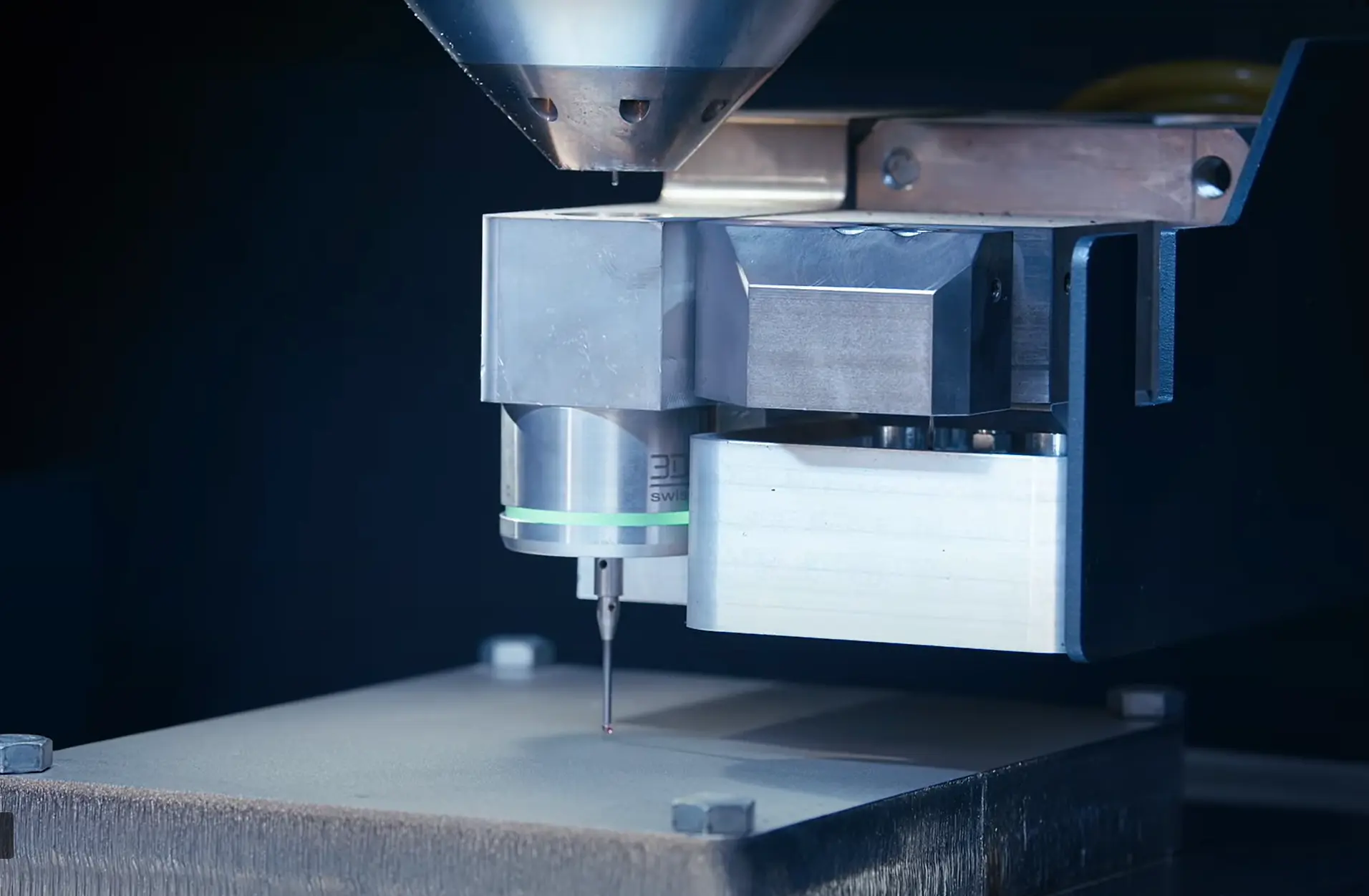

To develop a 3D printer, Meltio had to overcome key challenges such as ensuring precision, reliability, and adaptability while meeting the evolving needs of the manufacturing sector. Meltio developed a unique laser wire deposition process. Combined with advanced control systems and the ability to process multiple materials, it offers versatility for the metal parts production of various sizes and applications.

Meeting such challenges requires innovative engineering, thorough testing, and an understanding of market needs. These characteristics make Meltio's printers ideal for industries such as aerospace, automotive, and medical.

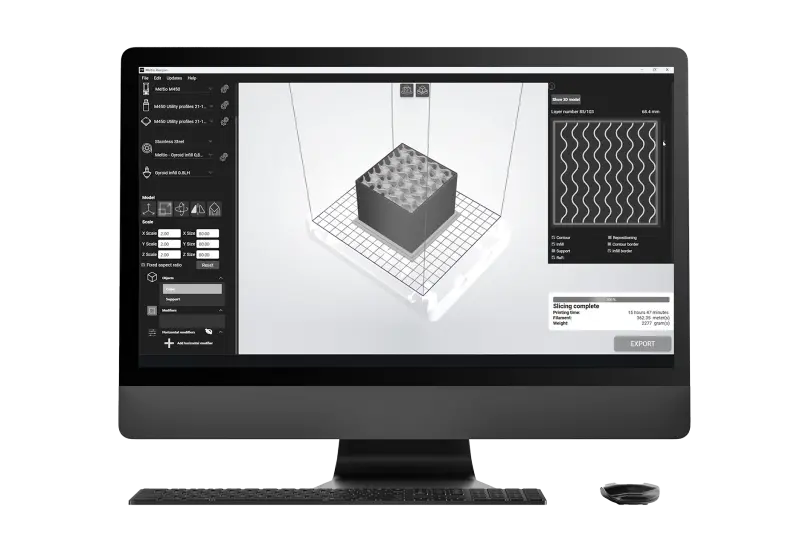

To ensure high-quality prints, Meltio has developed its own software, Meltio Horizon, which simplifies the operation of the 3D printers with its intuitive and user-friendly interface.

Meltio Horizon toolpath generator software

To achieve consistent prints, the 3D printer must contain high‐quality components that are both precise and durable. Magnetic encoders are perfect for this application, as they can operate in harsh industrial environments with oils, coolants or dust.

解決策

Meltio printers use advanced linear encoder systems to control the position and movement of the print head. High-quality magnetic encoders from RLS have been selected for their accuracy and reliability. The linear absolute system consists of the SAS10 magnetic scale and the LA11 readhead.

The encoder provides real-time position data, enabling precise adjustment and control. Thanks to the absolute encoder, the 3D printer can seamlessly recover from interruptions such as power outages or unexpected breaks in operation. By knowing the exact position of the print head at all times, the printer can resume the job exactly where it left off without the need for recalibration. The choice of quality components eliminates the risk of wasted material and time, enabling efficient and reliable production even under difficult conditions.

“After thorough testing and evaluation, the RLS encoders proved to be the best solution to improve the performance and accuracy of our 3D printers and met Meltio's high standards.” Manuel Galvez, Hardware Designer, Meltio

LA11 is a linear magnetic encoder system, which is highly reliable thanks to its non‐contact measuring principle and built‐in safety algorithms. The integrated status LED provides immediate visual feedback on the system status, simplifying installation, diagnostics and troubleshooting.

The LA11 offers a resolution of up to 0.244 µm and ensures precise control of the print head movement. Its non‐contact design guarantees long‐term reliability and wear resistance.

Complementing the LA11 readhead, the SAS10 magnetic scale is robust and fully enclosed. It can operate effectively in challenging conditions, as it consists of a stainless steel carrier and elastomer‐bonded ferrite. It is fully enclosed to IP67 standard and offers excellent protection against various contaminants.

The predefined lengths of the scale (up to 1.36 m) and compatibility with the LA11 readheads ensure easy installation and seamless integration with Meltio's 3D printing systems.

“We chose RLS products for their excellent reputation in providing high-quality and reliable magnetic encoders. Our decision was based on the need for precision and durability, which RLS encoders consistently meet.”Manuel Galvez, Hardware Designer, Meltio

結果

RLS magnetic encoders provide real-time data on the position and movement of the print head, enabling precise adjustments and control throughout the printing process. This accurate feedback is essential for print recovery, as the system can resume a print job exactly where it stopped in the event of a power failure.

The encoders meet the rigorous standards required in printing industries. Collaboration between Meltio and RLS reflects a shared commitment to innovation and progress in additive manufacturing technology.

“Our experience of working with RLS was very positive. The RLS team has supported us and helped us to integrate the encoders seamlessly into our systems. The reliability and performance of the RLS products have improved the quality, functionality, and precision of our 3D printers.”Manuel Galvez, Hardware Designer, Meltio

Future Goals

Meltio is focused on achieving new milestones in the additive manufacturing industry. The company's future goals include improving the capabilities of 3D printers, exploring new materials and expanding our market reach. The goal is to set industry standards for additive manufacturing and make metal 3D printing accessible to various industries. With its commitment to sustainability and efficiency, Meltio strives to lead the future of manufacturing, where the possibilities of 3D printing are vast and transformative.

About Meltio

Meltio was founded in Spain in 2019. The company develops and manufactures high-quality disruptive products aimed at high-profile industrial end customers and R&D organizations, such as universities and research-oriented companies.

For more information, visit meltio3d.com.

Meltio M600 industrial metal 3D printer