背景

As manufacturing shifts towards greater customization and the need for faster response times, there is also an increasing focus on improving working conditions, such as improving safety and addressing labor shortages. By automating repetitive and low-skilled tasks, employees can focus on more complex, creative or strategic activities that add more value to the company.

Industrial automation has made significant progress in recent years, mainly thanks to the emergence of collaborative robots (cobots). Cobots are redefining human-machine interaction and making production, manufacturing and assembly workplaces safer and more adaptable. Unlike traditional robots, which are often large and confined to safety zones, cobots are designed to work right alongside humans, performing tasks that require precision and adaptability.

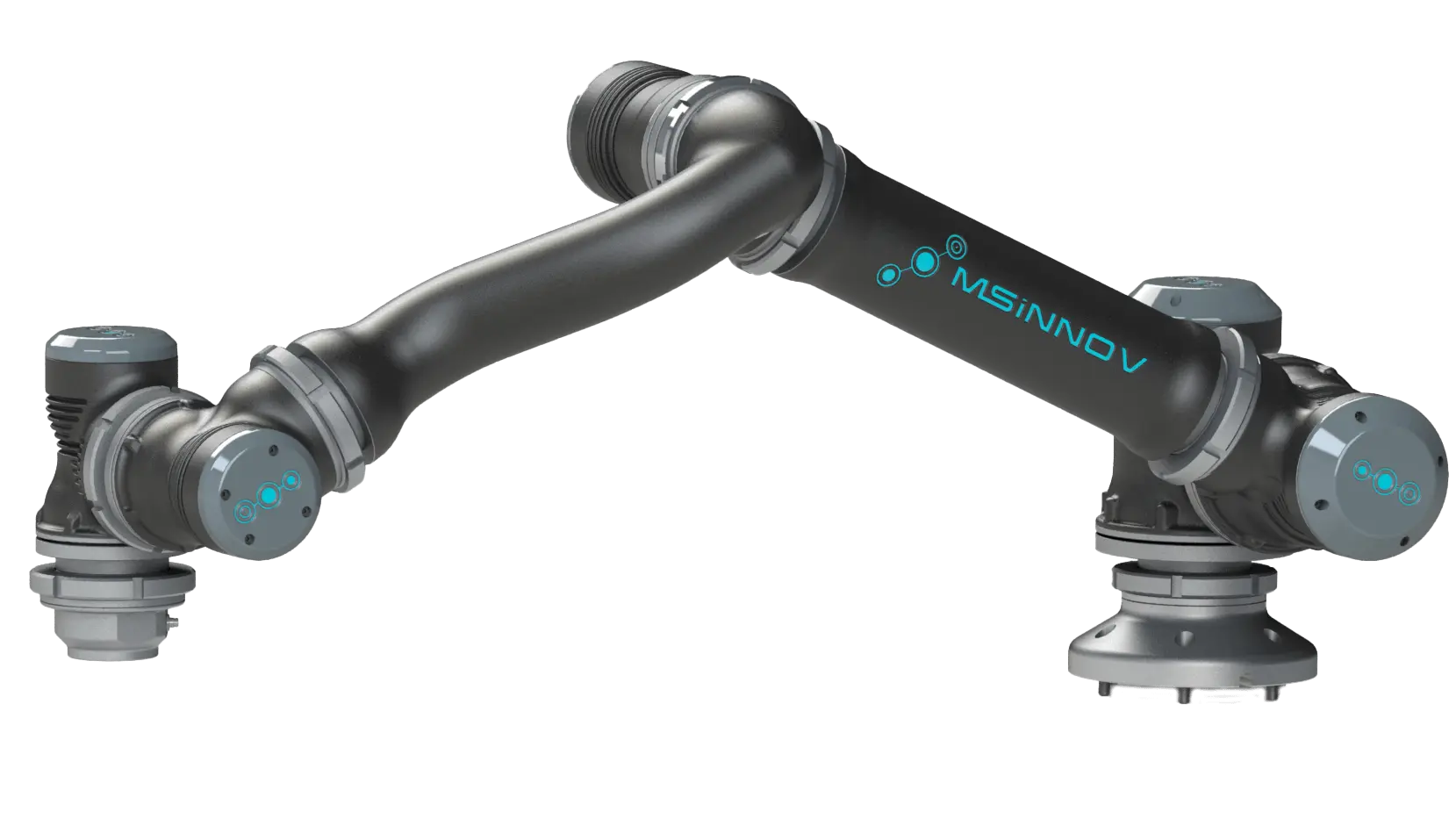

Founded in 2015, MS-Innov is the first French-owned company to manufacture and market a collaborative robot for industrial use. Its multi-axis collaborative robot MORFOSE uses the AksIM series magnetic absolute encoder, which ensures excellent performance, system safety and stability.

MORFOSE is a cobot that combines agility and efficiency while emphasizing human involvement. It has a modular design, i.e. there are no cables between the modules, which increases its adaptability and ease of use. This design allows it to be used in different industries and fulfill a variety of requirements by replacing multiple robot configurations.

The modular assembly system makes it possible to reconfigure the robot in different ways and extend its functionality beyond traditional robotics. Users can integrate the cobot into different production lines in less than 10 minutes, allowing quick adaptation to new tasks and offering endless possibilities for reconfiguring manufacturing processes.

MS-Innov is working with leading companies to develop more adaptable production processes while ensuring an environmentally friendly approach. In addition, the company is developing its own software called MARCUS, which provides an intuitive programming environment that allows users without specialized knowledge to easily program and control the robot. This approach makes human-machine interaction accessible to a wider audience.

MS Innov's cobot MORFOSE

挑战

No matter how good the design of a robot may be, it relies on the components used to maximise its functionality and efficiency. A robot usually consists of a main body (skeleton), a servo-driven system, a reducer and a control system. Requiring position feedback for real-time position tracking of each joint to the controller, an encoder is also a critical component to ensure the robot's accuracy.

The MORFOSE robots achieve a significant improvement in overall performance by using the AksIM series of magnetic encoders from RLS. Each module is equipped with two encoders: one located on the reducer and one directly on the motor. Compared to other robots, which typically have only one encoder, this design delivers even better results and reduces system error, resulting in a robot repeatability of ±0.1 mm, which is the gold standard for most market requirements.

MS-Innov team

解决方案

AksIM-2 is a true absolute encoder that does not require a battery backup - the absolute position is determined immediately when it is switched on. The encoder has several built-in self-monitoring functions that support the operational safety of MORFOSE robots.

The encoder and ring have been specially developed for integration into the reducer in a compact form, increasing the thickness of the joint by just 7 mm. The hollow ring allows cables to pass through, simplifying cable management and giving the customer more flexibility in system design. In addition, the lightweight encoder has significantly reduced the load on the joints, resulting in lower energy consumption.

RLS AksIM‐2 Rotary Absolute Magnetic Encoder

成果

The AksIM encoder has an outstanding performance specification that meets the most demanding requirements of robotic applications. The resolution is up to 20 bits, with a system accuracy of up to ±0.1° and a repeatability that is better than the resolution unit. With IP64 protection, it has excellent dirt resistance, enabling operation in harsh industrial environments.

“It has been a great partnership with RLS from the beginning with strong commercial and R&D support!”

Karine Wieder, Sales Director at MS-Innov

未来目标

MS-Innov will continue to innovate and develop new modules to adapt MORFOSE to new market requirements. The team is also looking to expand MORFOSE's capabilities for use in more sensitive environments to ensure the robot remains versatile and responsive to the changing needs of the industry.

About MS-Innov

MS-Innov is a pioneering French company specializing in the development and production of versatile collaborative robots designed for industrial use.