背景

Sparkfield 社は、先進的なロボット技術を融合し、多様な筋力トレーニングを可能にする「Sparkfield Core」という装置を開発、販売しています。2021 年の設立以来、米国、中国、欧州で特許を取得し、知的財産の拡充を続けています。

Sparkfield Core では、特に怪我のリスクが低く、効果的で多様なトレーニングが可能です。初心者のための安全で効率的なトレーニングから、プロアスリートのための高負荷なトレーニングまで、幅広く対応します。

Sparkfield Core は、ショルダープレス、ベンチプレス、ラットプルダウン、スクワット、デッドリフトといった「ビッグファイブ」を含む 20 種目以上のトレーニングを行うことができ、従来の専門的な器具の代替となり得る装置です。エキセントリックオーバーロード、等速性および等尺性トレーニング、スーパーセット、ドロップセットなどのトレーニングも可能で、ラボレベルのデータを活用したり、トレーニーのバイオメカニクスに応じて抵抗や動作を個別に調整したりできます。2023 年の初め、Sparkfield Core はスタジオ基準を満たす耐久性およびストレステストを完了し、CE 認証も取得しました。

Sparkfield Core

課題

Sparkfield 社は、顧客が好む環境で高品質な全身筋力トレーニングプログラムを提供することを目標としています。

スタンディングロー

Sparkfield 社は、自社開発の設計に特許を取得し、その設計に、最新の人と機械の連動の仕組み、データ分析を組み合わせています。Sparkfield Core は、ロボットの機械的自由度と柔軟性を備えており、水平、垂直そしてその組合せのあらゆる方向の動作が可能であることで、あらゆる筋肉へのアプローチが実現しています。

従来のプレートなどを使う機器とは異なり、Sparkfield Core では負荷を電子的に制御し、ソフトウェアで管理することで、あらゆる最新のトレーニング手法を可能にしています。特に、個人の筋力に応じた可変負荷プロファイルに対応している点が大きな特徴です。

個別化の精度は非常に高く、体の左右の力を 1 秒間に数千回、グラム単位で処理することで、水平方向と垂直方向のアンバランスを検出し、動作の正確性や疲労度を客観的に評価します。バランスの取れた発達を促進し、怪我のリスクを軽減しています。

解決策

Sparkfield Core は技術的には協働ロボットに非常に似ています。トレーニーが腕を押し引きする動作に合わせてスムーズかつ安全な軌道で動くようにしたり、トレーニーが加える力に応じて負荷を強めたり弱めたりするため、精度や安全機能が求められるロボットと同様の技術的要件が、Sparkfield Core にも必要となります。同社では、関節角度の検出と、センサー信号の整合性の確保にリダンダントタイプの AksIM を採用しています。継続的なモニタリングを行うことで、動作時の誤差を検出し、適切に対応することが可能になっています。

Sparkfield Core でのトレーニングの様子

AksIM-2 には、内部パラメータを常時チェックする自己モニタリング機能が搭載されており、内蔵 LED からエラーや警告といったステータスに関する情報を判断することができます。

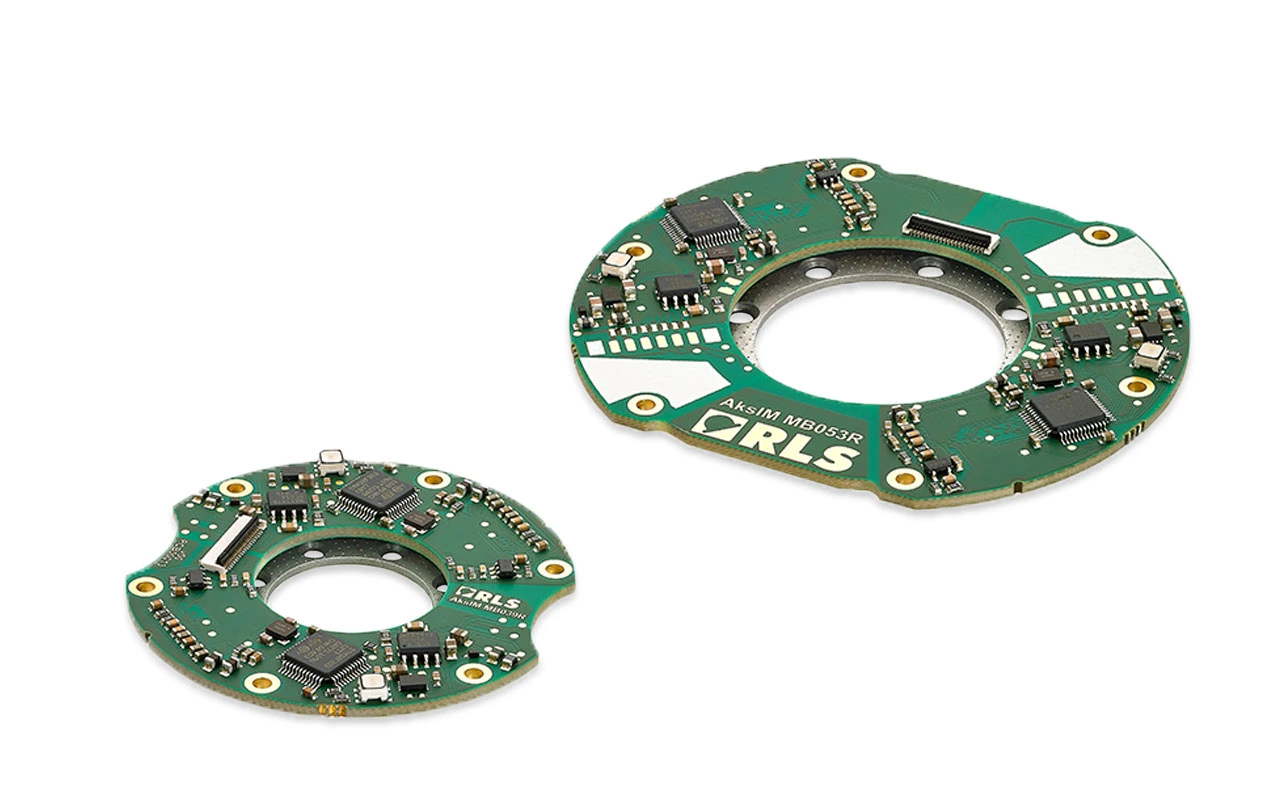

AksIM-2 リダンダントエンコーダシステムは、プリント基板上に配置した、電気的に互いに独立した 2 個のエンコーダモジュールと、1 個の磁気リングから構成されます。冗長構成は、互いに独立し、約 180°の位相差がある 2 チャンネルを通して位置を検出することができるため、安全性がより高く求められる用途に理想的です。リングに施されたデジタルバーコード磁化によって、1 個のリングで完全な冗長性が確保されます。

AksIM-2 リダンダントエンコーダ

また、薄型で非接触設計のため省スペース性に優れ、コンポーネントのサイズを小さくしたいときに特に便利です。

結果

Sparkfield 社にとっては、システム全体のコンセプトを考慮することが重要でした。フィットネス機器の性能を最適化するためには、必要な精度、データ速度、適切なインターフェースを確保することが不可欠でした。さらに、どのような機械部品が必要になるか、どの程度の精度が必要なのかも含め、システムへのエンコーダの統合も重要な要素でした。

Sparkfield 社は、少ない手間でキャリブレーションが可能で、素早く簡単にセットアップできることを理由に AksIM の採用を決めました。AksIM-2 を採用したことで、統合プロセスが効率化され、Sparkfield Core の総体的な精度と効率が向上しました。

今後の目標

パイロットフェーズの成功を受け、RLS センサーを組み込んだ初の量産を開始しました。初回出荷は 2024 年 9 月から始まります。Sparkfield Core は、限られたスペースで品質が重視される環境、例えばマイクロスタジオ、理学療法施設、企業の健康促進プログラムで真価を発揮します。中小企業でも、従業員にとって最適なトレーニングの機会を提供することが可能になります。

Sparkfield 社について

Sparkfield 社は、ロボット技術と最新のトレーニング方法を組み合わせて、狭い場所でも全身を鍛えられるコンパクトで効率的なフィットネス機器を提供しています。

詳細については、Sparkfield 社の Web ページをご覧ください。