Encoder Technology - HiLin

What is HiLin™?

HiLin is the best performance linear incremental magnetic encoder for use in harsh environments. The encoder system consists of a readhead and a scale. The readhead is available in incremental output format. There are three different scale options available and each of them has its advantages compared to the other.

Why HiLin™?

One of the main advantages of magnetic over optical encoders is that they can be used in harsh environments. The non-contact design of magnetic encoders eliminates wear and ensures years of reliable operation. With HiLin, we have taken this to a higher level.

Mechanical protection

We have developed a fully welded scale that protects the elasto-ferrite layer and keeps it free from contamination, making the system robust. When you need optimal performance in a harsh environment, HiLin with a fully welded scale is the right choice. Both the scale and the readhead have high IP protection and are resistant to various coolants and chemicals widely used in different industries.

Accuracy

The HiLin encoder offers the highest accuracy in our linear encoder portfolio. Depending on your (application) requirements, you can choose between the following options:

- Magnetic scale: the lightest and most compact option is a self-adhesive scale with an accuracy of ±10 µm/m in resolution, allowing for longer measuring lengths.

- Solid scale with/without cover foil: If you need higher accuracy, a solid stainless steel substrate scale with an accuracy grade of ±5 µm/m in resolution is the solution. The stainless steel substrate allows thermal expansion and improves thermal compensation.

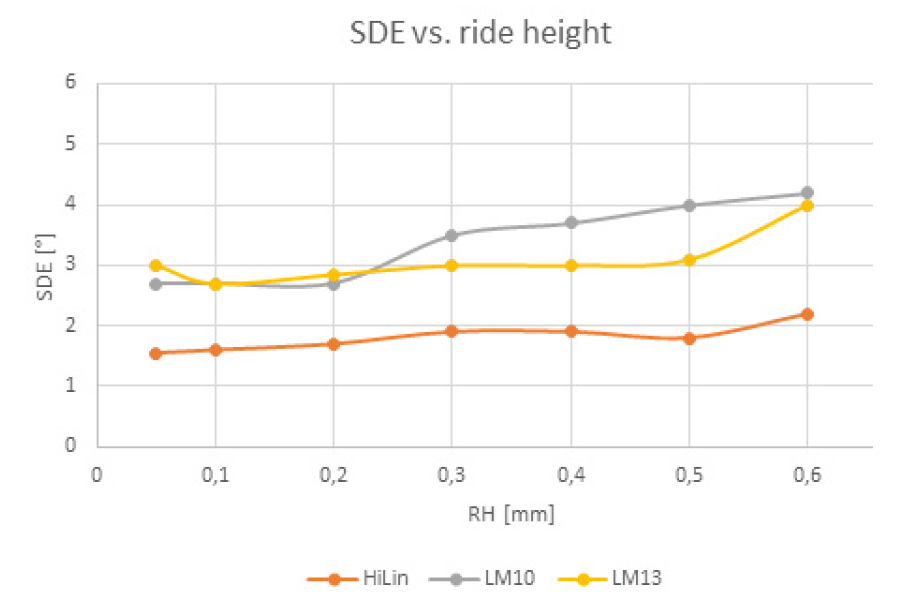

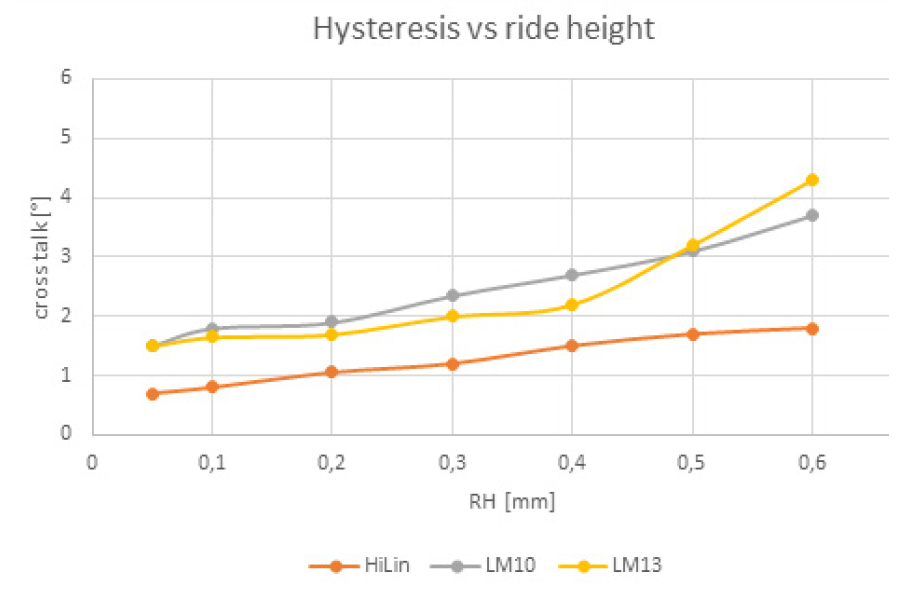

SDE & Hysteresis

The graph below shows a comparison of SDE and hysteresis between HiLin, LM10 and LM13. It is obvious that the performance is very good even outside the tolerances given in the data sheet.

High speed operation

The HiLin encoder is suitable for use in high speed applications. The HiLin has an advantage over RLS magnetic linear encoders. With a resolution of 1 µm, the HiLin can operate at speeds up to 25.28 m/s, while the LM10/13 operates at speeds up to 7.47 m/s.

Resolution

The encoder hardware is different from that of the LM encoder, which gives us greater freedom in choosing resolutions. Resolutions can be selected down to 0.1 µm (please contact us us for non-standard options). This is an advantage compared to other magnetic encoders.

Installation and handling

Easier installation and handling is an advantage of magnetic encoders over optical ones. The installation tolerances are larger for magnetic encoders compared to optical encoders, which helps the customer to integrate the encoder into his system without any special difficulties. Magnetic encoders do not require additional handling procedures like optical encoders, where the scale must be clean for optimum performance. Consequently, HiLin can operate in dirty environments and performance is not interrupted by dust or other non-magnetic contaminants on the scale.