Background

ThinGap, based in Camarillo, California, specializes in high‐performance motor kits for precision applications such as gimbals, optics and precision robotics. For over twenty years, the engineering, manufacturing and operations teams have been designing, developing and producing high quality engineered solutions.

As a wholly owned subsidiary of Allied Motion, ThinGap's market‐leadingproductsare expected to enhance Allied Motion's precision motion capabilities while providing integrated motion solutions. The combined units have the potential to enhance the company's capabilities in robotics, semiconductors and metrology, for which ThinGap's slotless motors are well suited.

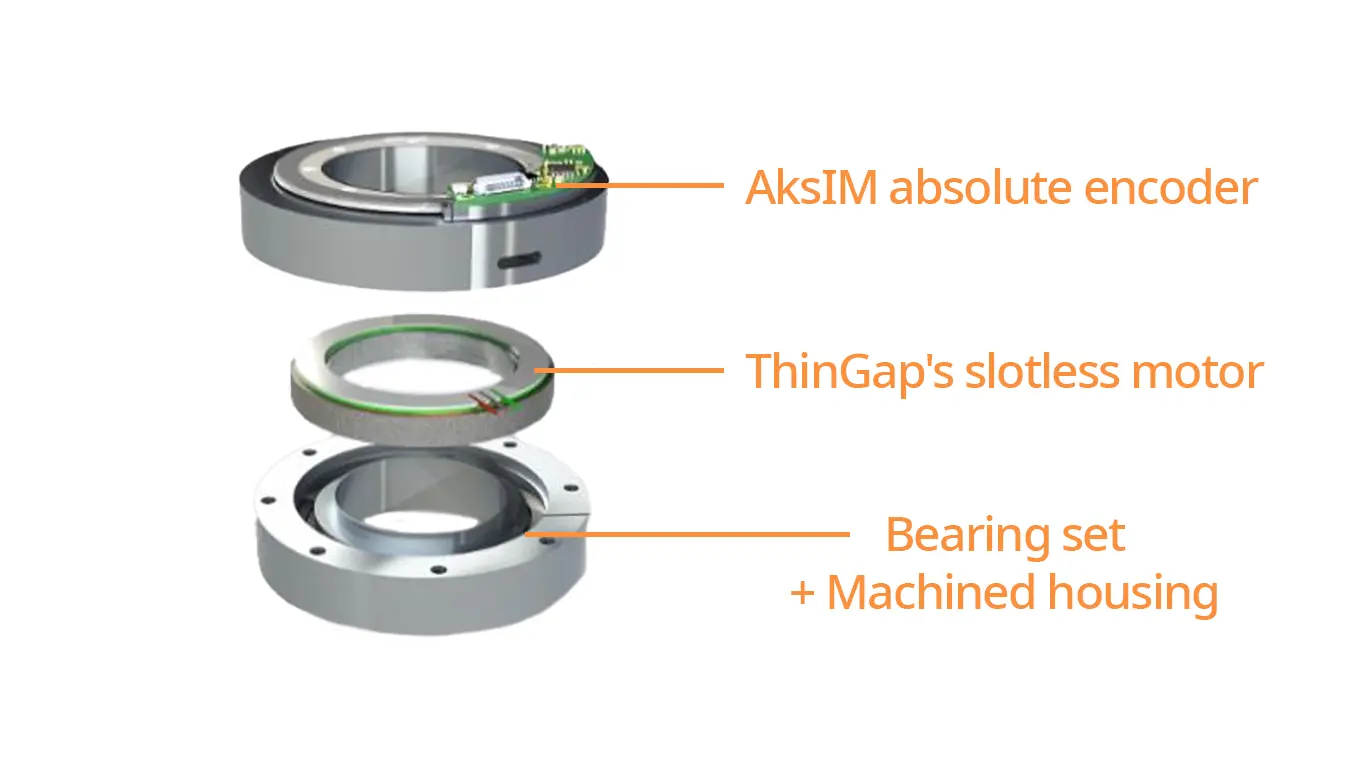

The key feature of the proprietary ThinGap motor technologies is the smooth, cogless motion enabled by the slotless architecture, where there are no iron teeth in the stator. This design ensures constant reluctance with respect to the angular position of the rotor and eliminates cogging during operation.

ThinGap's motors are available in a variety of sizes, power output, and form factors that are ideal for high‐end applications.

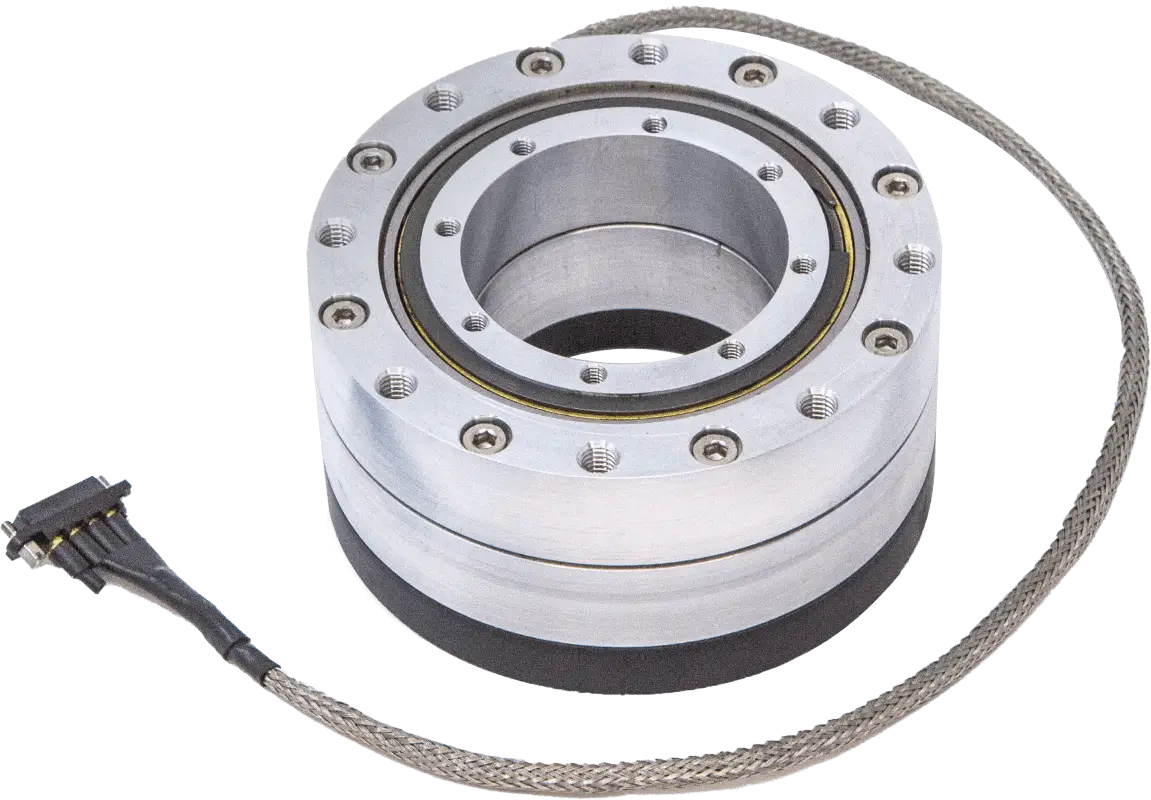

ThinGap's H‐LSI 75‐12 Turnkey Direct Drive Assembly

Challenge

Developing compact rotary actuators that are lightweight and capable of delivering high torque while having a large aperture requires an expert understanding of the technologies available for multiple components, including frameless motors and precision encoders and bearings. The additional requirement of cog‐free torque generation only narrows the solution space further.

ThinGap's patented wave wound coils provide an unmatched level of precision that cannot be achieved with standard motor technologies. The wave‐wound air‐core stator architecture and optimized rotor designs offer several key advantages over conventional slotted motors, including lightweight stators, no cogging torque and ultra‐high efficiency at high speeds. ThinGap also uses advanced Halbach array rotors that offer excellent performance improvements and weight savings.

The large internal aperture of the stator and rotor allows for deep integration into various systems. The motors also feature low harmonic distortion and exceptional phase balance, so that torque ripple is close to zero. Finally, they are characterized by a high torque‐to‐power ratio, which makes them efficient and powerful.

Many rotary actuators exist with some of the ThinGap attributes, but when it comes to unique size and cog‐free motion, off‐the‐shelf motors generally won't be sufficient, as the weight, precise motion and available through‐hole are often lacking.

Solution

ThinGap's motors achieve precision and efficiency with the integration of the AksIM‐2™ off‐axis rotary absolute magnetic encoder, which provides essential motion feedback for optimal operation. The encoder's large through‐hole and high accuracy make it a perfect fit for ThinGap's wave‐wound and air‐core stator architecture, enhancing the motor's zero cogging torque, low harmonic distortion, and high torque‐to‐weight ratio. This integration results in superior performance.

Precise rotational feedback from magnetic encoders is essential for ThinGap's motors. Permanent magnet motors, commonly referred to as BLDC (brushless DC) motors, require commutation to correctly apply the phase voltage to generate the commanded current flow and required torque. ThinGap specifically chose the RLS encoders because of their large through‐hole design, high precision, low cost and absolute sensing technology.

Position feedback by AksIM‐2™

The AksIM is a high‐performance absolute encoder developed for the precise rotary motion feedback. It is light‐weight and is characterised by a large through‐hole. The encoder offers absolute position accuracy and ensures reliable and precise measurements. Key benefits include a compact design, robust performance in challenging environments and easy installation. The AksIM encoder is particularly suitable for applications where high precision and reliability are required.

“The feedback from our end customers when using a ThinGap motor with the AksIM encoder is very positive. The motor has a fantastic dynamic current response and the encoder has a very low noise floor, making it a true high-precision combination.”

Joseph Kay, Director of Engineering, ThinGap, Inc.

RLS AksIM‐2 Rotary Absolute Magnetic Encoder

Results

The AksIM magnetic encoder offers numerous advantages that make it a robust solution for precision applications. Its true absolute system ensures accurate position data, which improves repeatability and consistency of performance. The built‐in self‐monitoring function increases reliability and safety, while its immunity to external magnetic fields maintains performance even in challenging environments. In addi tion, the encoder operates effectively over an extended temperature range, making it versatile for various applications.

“We are very happy with our experience due to the AksIM encoder performing better than expected and a wide range of products and sizes are available.”

Joseph Kay, Director of Engineering, ThinGap, Inc.

Future goals

ThinGap was acquired by Allied Motion, which opened up the opportunity to expand the business in many ways. A major focus in the coming years will be to expand higher level assembly options by integrating motor kits into housings, complete with bearing assemblies, encoders and even gears.

About ThinGap

ThinGap, based in Camarillo, California, provides high‐performance motor kits for applications that require smooth motion, precise actuation and deep integration.

For more information visit www.thingap.com.