Background

Torque motors are direct drive motors that eliminate the need for traditional gearboxes and offer smooth, precise motion control in a compact form. Their high performance with minimal mechanical complexity makes them ideal for applications such as robotics, medical devices, aerospace and automation. As industry demands more compact and efficient solutions, torque motors are becoming a key driver of innovation in all sectors.

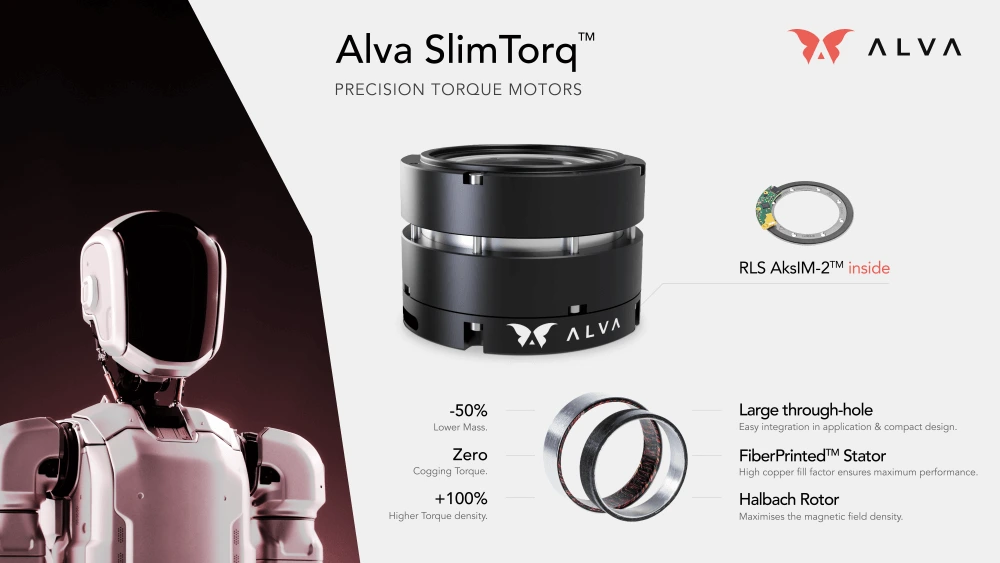

Alva Industries, based in Trondheim, Norway, designs and manufactures frameless, slotless motors for precision applications that require high torque in a lightweight and compact package. The company's proprietary FiberPrinting™ technology enables ironless and slotless motor windings with a copper fill factor of up to 60 %, setting a new standard for precision, torque density and adaptability. The unique production technology is a new benchmark for the development of customised motors.

Challenge

Years of intensive research and development were required for SlimTorq™ frameless motor range and to bring the FiberPrinting process from concept to scalable production. One of the main goals was to develop a motor that had zero cogging, high torque density and a slim, compact form factor, all without sacrificing performance or reliability.

To achieve this, complex integration issues had to be overcome, particularly in the area of precision feedback systems. The motors had to support a large through‐hole to accommodate various mechanical assemblies.

For Alva's customers – engineers often working under tight development timelines – having readily available evaluation units was essential for quickly testing and validating new technologies. Meeting this need made it crucial to select the right partner and sensing solution. To ensure seamless integration and high‐performance feedback, Alva chose RLS magnetic encoders as a key component in their product strategy and developed pre‐assembled evaluation kits.

Solution

The Alva evaluation kits are available in different motor sizes: from 25 mm to 160 mm in outer diameter. They are specifically designed for rapid prototyping, testing and validation.

The AksIM encoder provides true absolute position sensing in a compact format. It features integrated self‐monitoring capabilities and strong immunity to external magnetic interference, ensuring reliable performance even in demanding environments. Its slim profile and large central aperture align perfectly with the architecture of the SlimTorq motors, enabling seamless mechanical integration.

Thanks to the broad range of sizes offered in the AksIM product line, Alva can easily match each motor with the most suitable encoder. The result is a compact, precision‐engineered system that simplifies development while delivering high‐accuracy position feedback.

Position feedback by AksIM

AksIM is a non‐contact, true absolute encoder system that provides high‐resolution feedback with exceptional repeatability. By positioning the sensing electronics off the rotation axis, it enables a large through‐hole that integrates seamlessly with the physical design of most electric motors.

The encoder offers a resolution of up to 21 bits. Thanks to its integrated self‐monitoring system, the AksIM continuously checks internal parameters and can report errors or status conditions.

“RLS encoders and Alva motors have a great synergy when it comes to delivering high performance in a compact and low-profile form.”

Martina Gajšek, Marketing manager at RLS

It supports standard serial protocols such as BiSS C, Asynchronous serial (UART), SPI, PWM or SSI communication interfaces making it compatible with a wide range of motion controllers. In addition, its immunity to external magnetic fields ensures stable and interference‐free operation, which is a key benefit in systems that require both precision and robustness.

“The RLS encoders offer high value, providing exceptional performance and a wide selection of sizes while remaining cost-competitive.”

Nicolas Giraudo, Chief commercial officer at Alva Industries

Results

By choosing the AksIM for their evaluation kits, Alva Industries ensures that customers receive a high‐performance encoder that not only improves motor accuracy, but also simplifies system design. This synergy between encoder and motor design enables rapid prototyping, reduced integration complexity and overall system performance.

“RLS showed excellent responsiveness in communication and provided quick and precise answers. The comprehensive and well-prepared technical documentation made it easy for Alva to get started with RLS products and integrate them seamlessly into our systems.”

Anton Franzén, Director of product management at Alva Industries

Future goals

Alva Industries aims to expand its presence in the robotics, medical technology and lightweight automation sectors by further developing the SlimTorq portfolio and expanding production. The company continues to focus on innovation, operational excellence and building a world‐class team to achieve long‐term growth.

About Alva Industries

Alva Industries is a global manufacturer of frameless motors with its headquarters in Trondheim, Norway. Their patented technology enables compact and high‐efficiency motors.

For more information visit alvaindustries.com.