Background

Graspian redefines the capabilities of robotic grippers by adapting them to the objects they handle. This innovation reflects a broader shift in robotics, similar to the evolution from traditional industrial robots to collaborative robots (cobots). While the first robots were large, complex and difficult to integrate, cobots have set a new standard for accessibility and flexibility. Grippers represent the next stage of this transformation, enabling robots to interact with their environment with a level of dexterity and control very similar to the human hand.

By integrating numerous tactile sensors in each finger, the grippers can recognise subtle variations in touch and pressure. This inbuilt sensory feedback enables finer, more responsive handling of objects, even those with irregular shapes or delicate surfaces. Graspian's technology offers a new level of sensitivity and intelligence in robotic gripping, setting it apart from other automation solutions.

Graspian's intelligent tactile gripper

Challenge

The design of a tactile-sensitive gripper is a technical challenge. The system requires extremely precise control of finger movement and the ability to interpret sensor feedback in real-time. Graspian is pioneering in this area by embedding multiple tactile sensors into its grippers so that they can simulate a human-like sense of touch. As a tech company, they push the boundaries of robotics by continually developing advanced sensors and algorithms.

To meet different application needs, Graspian has developed several end-of-arm tools that can be customised to specific customer requirements to further increase the value and flexibility of its advanced gripper systems.

Accurate and timely feedback is crucial — without it, the gripper cannot effectively adapt to different object shapes, textures or levels of resistance. To achieve this level of control, a powerful, compact, reliable and easy-to-integrate motion feedback system is required. To fulfil these requirements, magnetic encoders from RLS were integrated into the finger mechanisms.

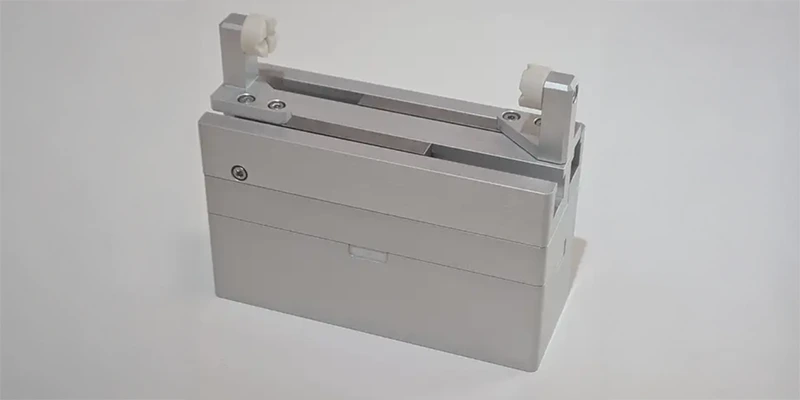

Graspian's parallel gripper tool

Solution

In order to achieve sensitive and adaptable manipulation, the encoder system must fulfil several important requirements. It must fit into the compact mechanical structure of the gripper, function reliably in demanding industrial environments and integrate smoothly into the hardware and control software. Without such a feedback loop, the gripper would not be able to deliver the sensitivity and precision required for complex handling tasks.

RMB20 encoders provide important real-time position feedback and enable a closed-loop control system that controls the movement of each finger with high precision. This allows the gripper to dynamically adapt to the object being gripped, supporting fine motor control and responsive behaviour.

Graspian chose RLS encoders for their short lead times, straightforward and simple mechanical and software integration, reliable performance and cost efficiency - even at low production volumes. These benefits enable Graspian's grippers to perform complex, nuanced movements with consistent accuracy. This also enhances the robot's ability to perform increasingly demanding gripping tasks with intelligence and reliability.

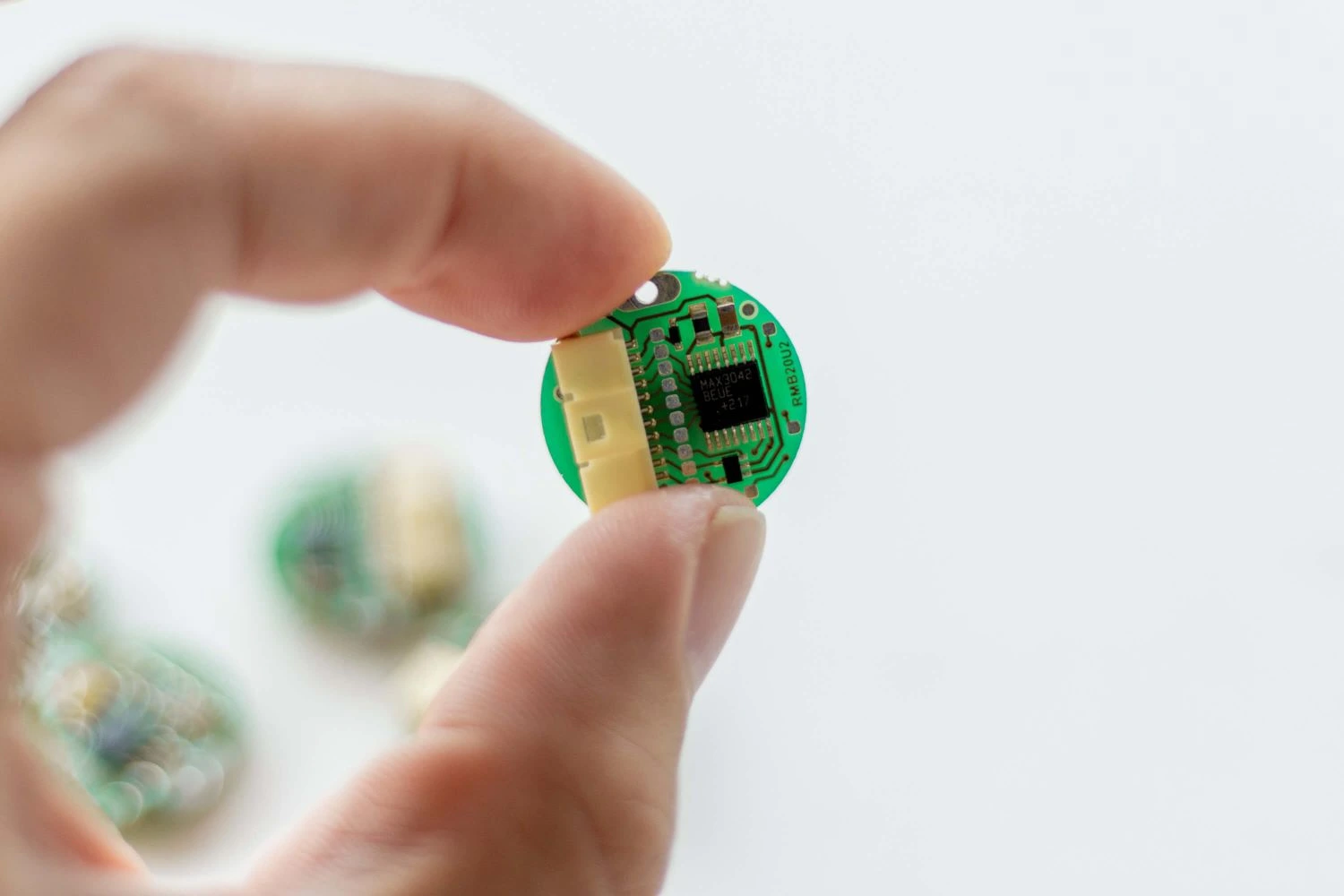

Position feedback by RMB20

The RMB20 magnetic rotary encoder module is a compact and powerful solution for the precise detection of rotary movement. With its 20 mm circular PCB design, it is ideal for applications where space is limited. Despite its small size, the encoder offers a resolution of up to 13 bits (8,192 counts per revolution) and supports speeds of up to 60,000 rpm, enabling accurate, real-time position data in fast and dynamic environments.

One of the key benefits of the RMB20 is its wide range of electrical output formats, making it exceptionally versatile. These include analogue sine/cosine, binary parallel, incremental quadrature, linear voltage, RS422 differential and SSI. Thanks to this flexibility, the encoder can be adapted to a variety of control systems and communication protocols used in industrial and robotic applications.

RMB20 magnetic rotary encoder module

“To grip accurately and precisely, control is key. And to have control, feedback is crucial. The RLS encoders are an important part of the control loop, managing the movement of the fingers.” says Anders S. Frandsen, CEO of Graspian.

RMB20 also offers an accuracy of up to ±0.5°, which is essential for applications that require precise motion control. Designed for reliability, the encoder operates consistently over a wide operating temperature range of −40 °C to +125 °C, making it highly durable.

Designed with integration in mind, the RMB20 is easy to implement both mechanically and electrically. These features make it the ideal choice for advanced automation applications that require compact size, precision and robust performance.

Results

In order to achieve accurate and precise gripping, full control over the movement of the gripper's fingers must be guaranteed. Effective control is only possible with reliable feedback. By integrating RLS magnetic encoders into their system, Graspian has established a high-performance feedback loop that enables the fine-tuned, adaptive finger motion their application requires.

“The cooperation with RLS was good. The online configurator made purchasing straightforward, and having local support along with short lead times was a great experience for us.” Anders S. Frandsen adds.

Future Goals

Graspian plans to expand its presence in strategic markets, strengthen its internal development capabilities, and actively pursue partnerships for collaborative innovation.

About Graspian

Graspian is a Danish robotics startup that develops innovative, touch-sensitive grippers. It offers customised end-of-arm tools for robotic tasks that require more than a standard solution.

For more information about Graspian visit: www.graspian.com.