Magnetoresistive effect

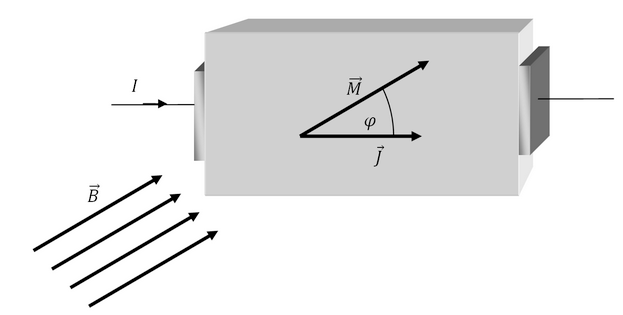

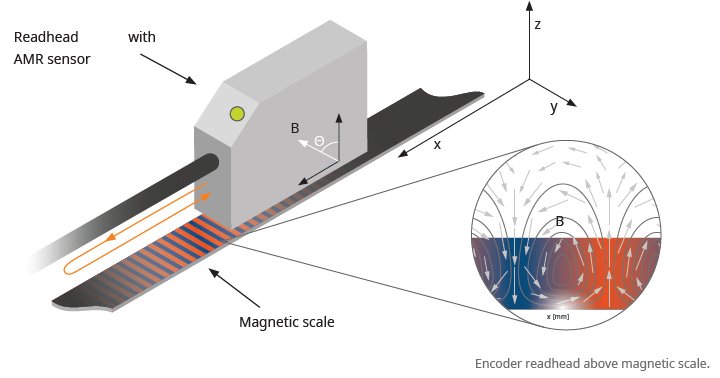

A magnetoresistive sensor consists of a resistor made of magnetically sensitive alloy strips such as nickel iron (NiFe). An external magnetic field stresses the magnetic domains in NiFe and reduces the resistance of the material. When the field is removed, the resistance quickly normalizes, making it a useful tool for magnetic field detection. There are three common types of magnetoresistive effects: anisotropic (AMR), tunneling (TMR) and giant magnetoresistance (GMR). AMR sensors are most commonly used in the encoder industry.

The change in resistance is independent of the polarity of the magnetic field. For example, a 32-pole ring generates 32 pulses per revolution, whereas Hall sensors with 32-pole encoder wheels would only generate 16 pulses per revolution. This makes magnetoresistive sensors ideal for incremental applications.

But the technology also has disadvantages. Magnetoresistive sensors, although manufactured in semiconductor technology, are not solid-state devices, so they cannot be integrated directly into the processor at the chip level. As discrete sensors, they are larger, more difficult to manufacture and require additional support circuits. This increases both costs and complexity.

Open encoder selector All products