Background

Hyperion Robotics is an interdisciplinary student team from the University of Western Macedonia, focused on designing and building autonomous robots for international competitions and research initiatives. In their 2023 Eurobot project, the team developed two fully autonomous robots capable of completing complex tasks under strict time constraints, where even minor positional errors could cost valuable points.

Eurobot itself is a global amateur robotics competition that brings together innovation, teamwork and high-technology problem-solving. Founded in 1998, it welcomes student teams and independent clubs from around the world, offering a dynamic environment where creativity, engineering skills and collaboration come together.

Hyperion Robotics team

Challenge

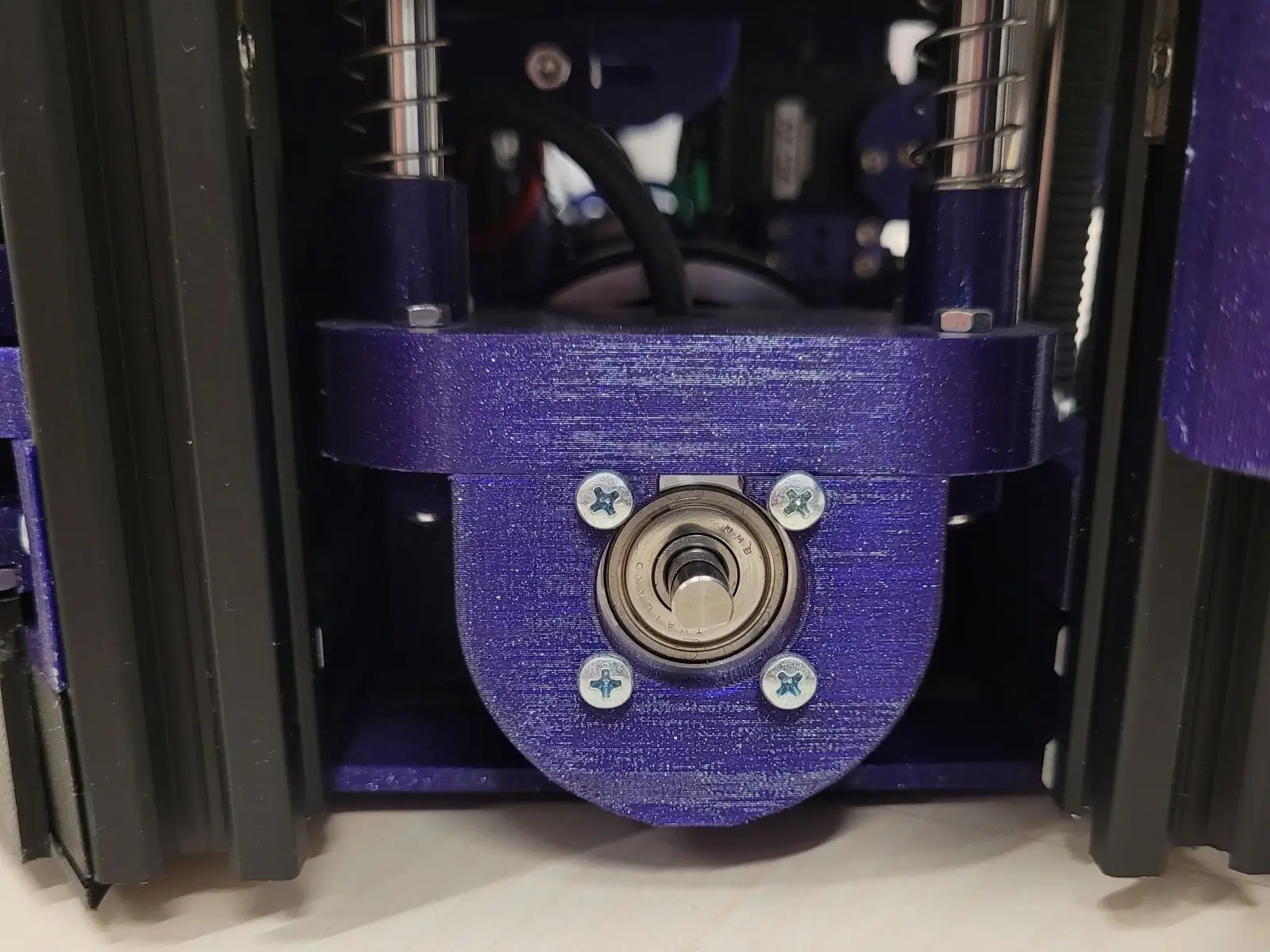

Building autonomous competition robots is a demanding task, and one of the biggest challenges is achieving a reliable and accurate movement system. For a differential-drive robot, both wheels must rotate at exactly the same speed in order to move straight. To achieve this, the Hyperion Robotics’ team used two RLS RE36 absolute magnetic encoders, each mounted on a suspension system next to the wheels.

Special 3D printed wheels were mounted on the encoders, which were uncoupled from the motor wheels so that they could spin without the influence of the motors. Combined with the suspension system, which ensured constant ground contact, the encoders could accurately measure forward and backward displacement as well as the rotational movement.

For moving forward a PID controller was used with the encoder difference as the input and the output was used to drive each motor which, when tuned correctly, led to a straight and very fluent movement.

Collecting and sorting discs

Solution

RE36 rotary magnetic shaft encoder is a compact and robust absolute encoder designed for precise position measurement in demanding environments. Its non-contact magnetic sensing principle ensures long-term reliability, while the integrated electronics provide accurate absolute position feedback without the risk of missed pulses.

It offers high immunity to shock, vibration and contamination, making it ideal for robotics applications where stability and durability are essential. Its shaft design allowed the team to attach custom measuring wheels directly to the encoder, enabling precise and consistent tracking of the robot’s motion.

With a body diameter of just 36 mm and IP53 dirt immunity, the RE36 ensures long-term durability even in challenging environments. It provides accuracy up to ±0.3° and supports speeds up to 20,000 rpm. It is available with a range of absolute, incremental and linear output formats, making it easy to integrate into different control systems.

The encoder’s low inertia, simple installation and availability in both binary and decimal resolutions make it well-suited for precise robotic motion control. While commonly used across industries such as marine, medical, printing, industrial automation and metalworking, the RE36 proved equally effective in Hyperion Robotics’ autonomous competition robots, where its compact size and reliability were essential for consistent movement measurement.

“Our experience working with RLS has been nothing short of phenomenal. Once we selected the encoder model, everything from delivery to integration went smoothly.”

George Ktistakis, Head of Engineering at Hyperion Robotics

RE36 Integration

Results

The team chose the RE36 model for several important reasons. Since absolute position feedback was essential for the project, an absolute encoder was the only viable option.

“Throughout testing, the encoders proved so reliable that whenever we encountered movement issues, they were always the last component we needed to check.”

George Ktistakis, Head of Engineering at Hyperion Robotics

Finally, a shafted encoder was necessary because the encoders were connected to their own independent measuring wheels rather than being mounted on the motor shaft. This choice ensured stable, accurate motion measurement and contributed significantly to the overall performance of the robots, concluding the project with a system the team could trust.

Future goals

The team is highly motivated for the next stages of their robotics journey. After gaining valuable experience from this year’s Eurobot competition, they are already applying what they’ve learned as they begin developing their next generation of robots. Their upcoming goal is to participate in Eurobot 2026, which will take place in France. The theme for the competition, “Winter Is Coming,” presents new challenges that the team is eager to explore as they continue improving their designs and capabilities.

About Hyperion Robotics

Hyperion Robotics is a volunteering and interdisciplinary student team of the University of Western Macedonia. It was founded by undergraduate students in 2014 and currently consists of 8 members and a mentor.

For more information visit robotics.uowm.gr.