How to select an encoder

Selecting the right encoder for your application can be a stressful task. With a variety of outputs, reading types and encoder body options to choose from, how can one get the best sensor for his application?

Some of RLS encoders: AksIM-2, OnAxis, LM10

STEP 1: CHOOSE THE TYPE OF ENCODER

The linear encoder moves along the scale or ring and rotary encoder rotates around its axis. Learn more...

- Encoding principle:

- Incremental

- Absolute

The difference between incremental and absolute encoders is similar to the difference between a stopwatch and a clock. Learn more...

- Working principle:

- Magnetic

- Optical

- Inductive

- Laser

The position of the encoder can be measured using various physical principles. The information can be transmitted from the actuator to the readhead via light beam, electric current, electromagnetic field, induction, etc.

STEP 2: DEFINE SPECIFICATIONS OF ENCODER

- Resolution:

- High

- Medium

- Low

The resolution is the smallest movement detected by the encoder. It is measured differently depending on the type of encoder.Learn more...

- Accuracy

The deviation between the actual position and the readout position from the encoder.Learn more...

- Repeatability

The difference in the reported position of the same physical point from multiple measurements by traveling in the same direction under the same conditions. Learn more...

- Safety

- Redundancy

- SIL (Safety Integrity Level)

- Others

- Interface

- Size

- Environment (speed, temperature, IP protection, pressure, resistance against chemicals...)

STEP 3: DECIDE ON ADDITIONAL FEATURES OF ENCODER

- Self-calibration

- Diagnostics (LED, software)

- Zeroing

-

Range:

- Single-turn

- Multi-turn

With a singleturn encoder, the output codes are repeated with each revolution of the encoder shaft. With multiturn absolute encoders, the output is unique for each shaft position at each revolution up to a certain number of revolutions (e.g. 4096).

There are many types of encoders, intended for various purposes, applications and end users.

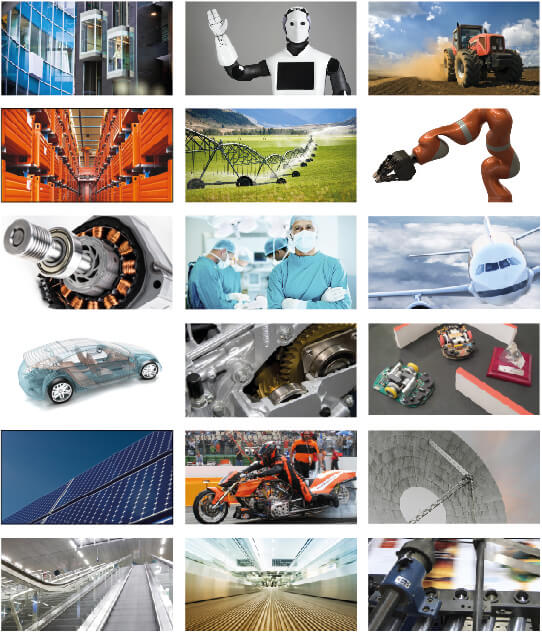

Most common applications for magnetic encoders: motion control, robotics, agriculture, medical, aerospace, automotive ...

Open encoder selector All products